In the fields of power systems and industrial manufacturing, the “busbar” is like an unseen hero, silently carrying immense energy and precise operations. From towering substations to complex and sophisticated electronic equipment, from the heart of the urban power grid to the core of automated production lines, the busbar, in its diverse forms and functions, builds a crucial network for the transmission of energy and signals. And through advanced technology and outstanding craftsmanship, High Machinery Company has become a leader in busbar processing equipment, providing a solid guarantee for the efficient application of busbars in various industries.

1.Definition and Essence of Busbars

From a basic perspective, a busbar is a conductor that collects, distributes, and transmits electrical energy or signals. It is like the “main road” in a circuit, connecting various electrical devices and undertaking the tasks of transferring and transmitting electricity or signals. In the power system, the core function of a busbar is to collect the electrical energy output by different power sources (such as generators and transformers), and distribute it to various power consumption branches; in electronic devices, the busbar is responsible for transmitting data and control signals between different chips and modules, ensuring the normal operation of the equipment.

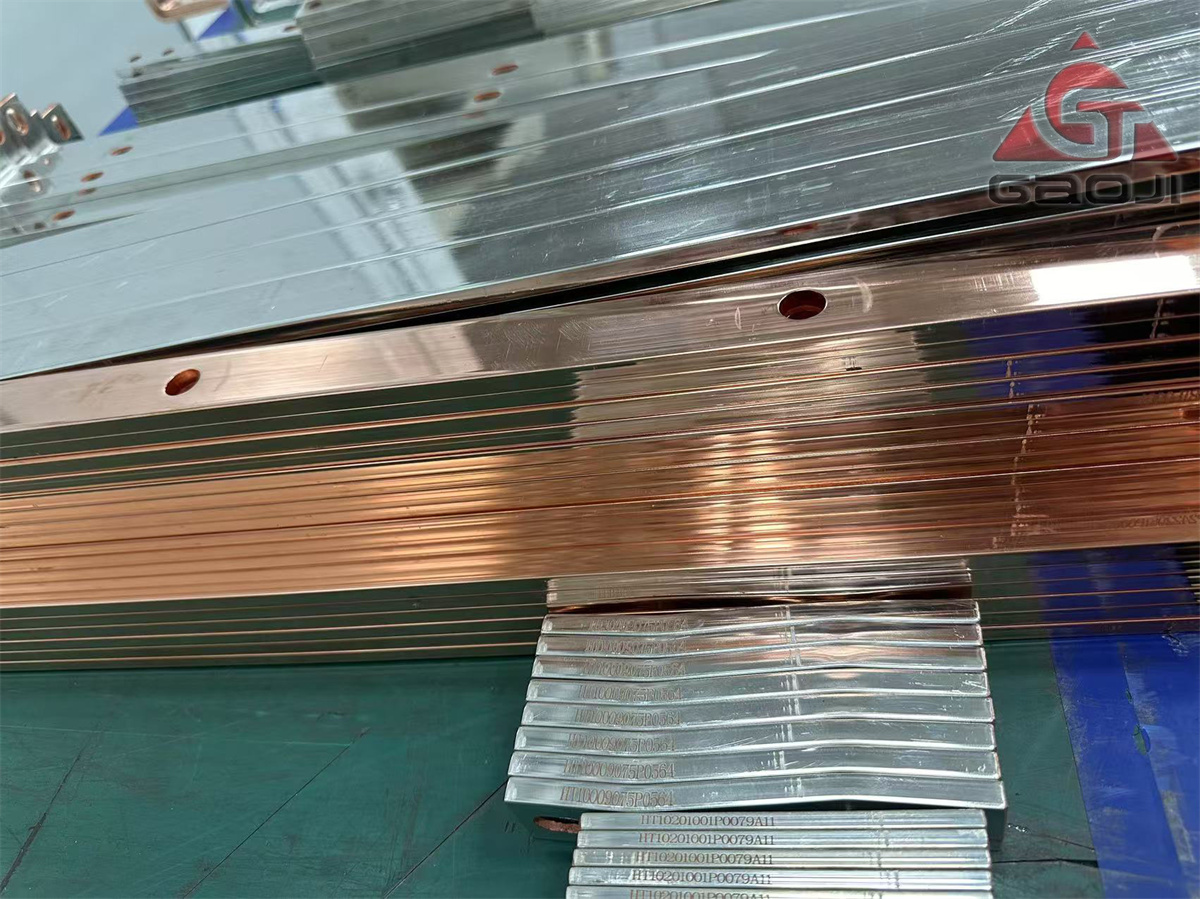

From a material perspective, the common materials for busbars include copper and aluminum. Copper has excellent conductivity and corrosion resistance, low transmission loss, but is more expensive. It is often used in scenarios where strict requirements are imposed on the quality of electric energy transmission, such as precision electronic equipment and high-end data centers. Aluminum has a low density and relatively low price. Although its conductivity is slightly inferior to that of copper, it becomes the preferred material in power engineering where large currents, long distances, and cost sensitivity are involved, such as high-voltage transmission lines and large substations.

Gaoji Company has a profound understanding of the impact of busbar material properties on applications. Its developed busbar processing equipment can precisely and efficiently handle copper and aluminum busbars, meeting the processing accuracy and efficiency requirements of different customers for busbars, and ensuring the stable operation of busbars in various complex environments.

2.Buses in the Power System: The Core Hub of the Grid

In the power system, the busbar is the core component of substations and distribution stations. According to voltage level and function, it can be divided into high-voltage busbar and low-voltage busbar. The voltage level of the high-voltage busbar is usually 35 kilovolts or above, and it is mainly used in power plants and ultra-high voltage substations, undertaking the task of collecting and transmitting large-scale electric energy over long distances. Its design and operation directly affect the stability of regional and even national power grids. The low-voltage busbar is responsible for safely and efficiently distributing electric energy to end users such as industrial plants, commercial buildings, and residential areas.

In terms of structural form, power busbars are divided into hard busbars and soft busbars. Hard busbars mostly use rectangular, trough-shaped or tubular metal conductors, which are fixed and installed through insulators. They have the characteristics of compact structure, large current-carrying capacity and high mechanical strength, and are suitable for indoor substations and distribution devices with limited space and large currents; soft busbars are generally composed of multiple strands of twisted wires, such as steel-cored aluminum stranded wire, which are suspended on the framework by insulator strings. They have the advantages of low cost, simple installation and adaptability to large-span spaces, and are often used in outdoor high-voltage substations.

Gaoji Company provides comprehensive solutions for the processing of power system busbars. Its flagship product, the intelligent busbar processing line, enables the entire process of busbar assembly – from automatic material retrieval and loading, to punching, marking, chamfering, bending, etc. – to be fully automated. After the processing instructions are drawn by the server and issued, each link works closely together. Each workpiece can be processed in just one minute, and the accuracy rate of processing meets the standard at 100%, effectively ensuring the high-quality supply of power system busbars.

3.Busbar in Industrial Manufacturing and Electronic Equipment: The Bridge Connecting Signals and Energy

In the fields of industrial automation and electronic equipment, the bus plays the role of a “neural network”. Taking industrial automation production lines as an example, fieldbus technology is a typical application, such as PROFIBUS, CAN bus, etc. They can connect sensors, actuators, controllers and other devices into a network to achieve real-time data transmission and coordinated control of the equipment, greatly improving production efficiency and automation level. In the computer field, the system bus on the motherboard is responsible for connecting the CPU, memory, graphics card, hard disk and other key components. The data bus transmits data information, the address bus specifies the data storage location, and the control bus coordinates the operations of each component to ensure the efficient operation of the computer system.

The busbar processing equipment of Gaoji Company is widely used in industrial manufacturing and electronic equipment industries. For instance, its CNC busbar punching and shearing machine can perform processes such as punching, slotting, corner cutting, cutting, embossing, and chamfering on busbars with a thickness of ≤ 15mm, a width of ≤ 200mm, and a length of ≤ 6000mm. The accuracy of the hole spacing is ±0.1mm, the positioning accuracy is ±0.05mm, and the repeat positioning accuracy is ±0.03mm. It provides high-precision busbar components for industrial equipment manufacturing and electronic equipment production, helping to upgrade the industrial intelligence.

CNC busbar punching and shearing machine

4.Innovation in Bus Technology and Future Trends

With the vigorous development of emerging fields such as new energy, smart grids, and 5G communication, busbar technology is also constantly innovating. Superconducting busbar technology is a highly promising development direction. Superconducting materials have zero resistance at their critical temperature, enabling lossless power transmission, significantly improving power transmission efficiency and reducing energy loss. At the same time, buses are moving towards integration and modularization, integrating buses with circuit breakers, disconnectors, transformers, etc., to form compact and intelligent distribution equipment, reducing the floor space, and improving the convenience and reliability of operation and maintenance.

Gaoji Company has always kept pace with the technological innovation trends in busbars, continuously increasing its research and development investment, with the annual investment in technology accounting for more than 6% of its sales revenue. In December 2024, the company obtained the patent for “A flipping feeding mechanism for a fully automatic CNC busbar bending machine”. This mechanism integrates the functions of feeding and flipping, combines with advanced sensor technology, can monitor the product status in real time and automatically adjust, effectively improving production efficiency and processing accuracy, meeting the requirements for bending complex-shaped busbars, and injecting new impetus into the development of busbar processing technology.

Although the busbar may seem ordinary, it plays an irreplaceable and crucial role in the energy supply and industrial production of modern society. With sixty independent research and development patents, a market share of over 70% in China, and remarkable achievements in exporting products to more than a dozen countries and regions around the world, Gaoji Company has become an important force driving the advancement and application expansion of busbar technology. In the future, Gaoji will continue to focus on areas such as intelligent processing and unmanned workshops, providing more intelligent, convenient and aesthetic industrial equipment for various industries. Together with the busbar, it will become a powerful driver of the energy revolution and the intelligent transformation of the industrial sector.

Post time: Jun-19-2025