Feb 22th, the fully automatic busbar processing system project developed by Shandong Gaoji Industry Machinery Co., ltd and DAQO group started the first phase field trial in DAQO group Yangzhong new workshop.

Founded in 1965, DAQO Group has become a leading manufacturer in Electrical Equipments, New Energy and Railway Electrification field. Main products include HV, MV & LV switchgear, intelligent components, MV LV busbar, power system automation, transformer, high-speed railway electrification equipment, polysilicon, solar cell, PV module and grid connection system. DAQO New Energy Co., Ltd. (DQ) was listed on the New York Stock Exchange in 2010.

The main object of this field trial is to inspect the system development and operation under normal working intensity of the first phase.

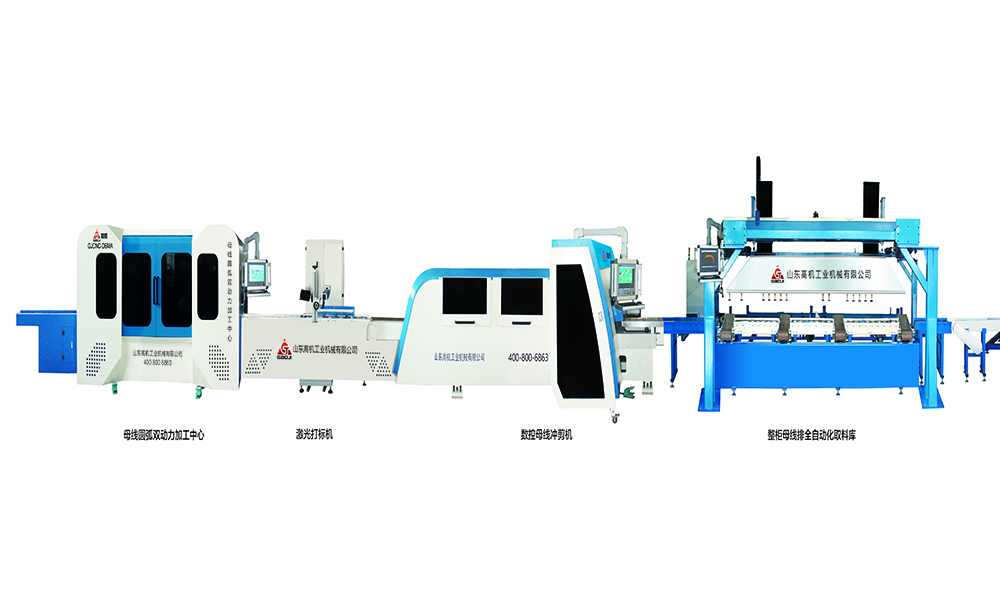

In this trial the system is made up of five main parts: the automatic busbar warehouse, the busbar punching shearing machine, the duplicate busbar milling machine, the laser marking machine and the control system.

The automatic busbar warehouse is a new machine for Shandong Gaoji company, it was developed in 2021, the main purpose of developing this machine is to reduce the damage made by carrying the busbar by hand, and also could reduce the labour intensity to make the whole process more effective.

As we all know, the copper busbar is heavy and a little soft, a 6m long busbar is easily deformed during manual delivery, with the pneumatic chuck the busbar will be easily removed and reduce the possible damage on the busbar surface.

The punching shearing machine and the duplicate busbar milling machine are both specially prepared for the system, these machines are shorter and more effective than the normal model, and this character also makes them more flexible during site arrangement。

And the laser marking machine of the system is connected with the main control computer, which is able to mark every workpiece with unique QR code, making the source inspection possible and easy to operate.

When all the processes are done, the workpiece will be piled up on the collecting wheelbench, it will be very convenient to take the workpiece to the next process.

Another important part of the field trial is the managed system which will control all these machines and connect the system to the database, the control system based on the MES system, developed by the engineers of Shandong Gaoji, Siemens, and DAQO group.

During development we integrated our rich service experience into the system, making the new system more efficient, reasonable, sensible during processing, reducing possible error and cost caused by manual operation, experience difference, and material difference as much as possible.

This is our new fully automatic busbar processing system for the first phase, and the second phase will add another new machine and more touch screens into the system, the whole processing cycle will complete. For the control system, real time supervision and real time adjustment will be realized, the control of production will be more convenient and reliable than before.

Post time: Feb-25-2022