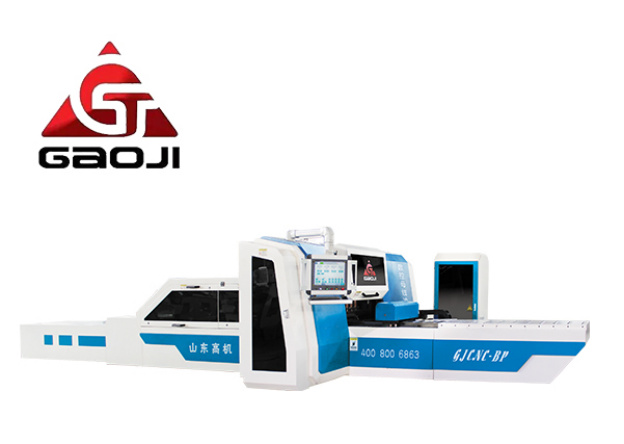

The GJCNC-BP-60 CNC Busbar Punching and Shearing Machine launched by Shandong Gaoji Industrial Machinery Co., Ltd. (hereinafter referred to as “Shandong Gaoji”), a leading enterprise in China’s CNC busbar processing equipment industry, integrates multiple patented technologies and cutting-edge industrial designs. It accurately addresses the pain points of traditional busbar processing, such as low efficiency, insufficient precision and low automation level, providing efficient and precise processing solutions for electrical equipment manufacturing in fields like new energy, rail transit and smart grids. This further demonstrates Shandong Gaoji’s R&D strength and innovation capability in the field of industrial automation equipment.

As a high-tech enterprise with more than 20 years of establishment, Shandong Gaoji has been deeply engaged in the R&D and manufacturing of CNC busbar processing equipment. Supported by the accumulation of multiple patented technologies, ISO9001 quality management system certification, and a large-scale production capacity of 800 sets per year, it has become one of the largest production and R&D bases for CNC busbar processing equipment in China. The newly launched GJCNC-BP-60 CNC Busbar Punching and Shearing Machine is a benchmark product developed based on in-depth insight into industry needs and years of production experience, achieving a comprehensive upgrade from core performance to operational experience.

Multi-Dimensional Technological Innovation, Solving Industry Processing Pain Points

As the “blood vessel” of electrical equipment, the processing quality of busbars directly determines the electrical performance and safety stability of equipment. Aiming at industry pain points of traditional equipment, such as long mold change time, poor processing precision, high energy consumption and noise, the GJCNC-BP-60 has achieved a dual leap in processing efficiency and quality through five core technological breakthroughs.

In terms of automation and efficiency, the equipment adopts an integrated design, integrating full-process functions including automatic feeding, precise positioning, intelligent clamping, punching and shearing, and automatic material receiving, truly realizing “one-key start and full-process unattended operation”. Compared with the 5-minute processing time of a single busbar by traditional equipment, the GJCNC-BP-60 shortens the processing time to less than 1 minute, improving efficiency by more than 5 times. Equipped with a mold library of 8 punches + 1 shear or 7 punches + 1 shear + 1 press, it supports the processing of round holes, slotted holes, square holes and special-shaped holes without stopping for mold change, greatly reducing production interruption time and meeting mass production needs.

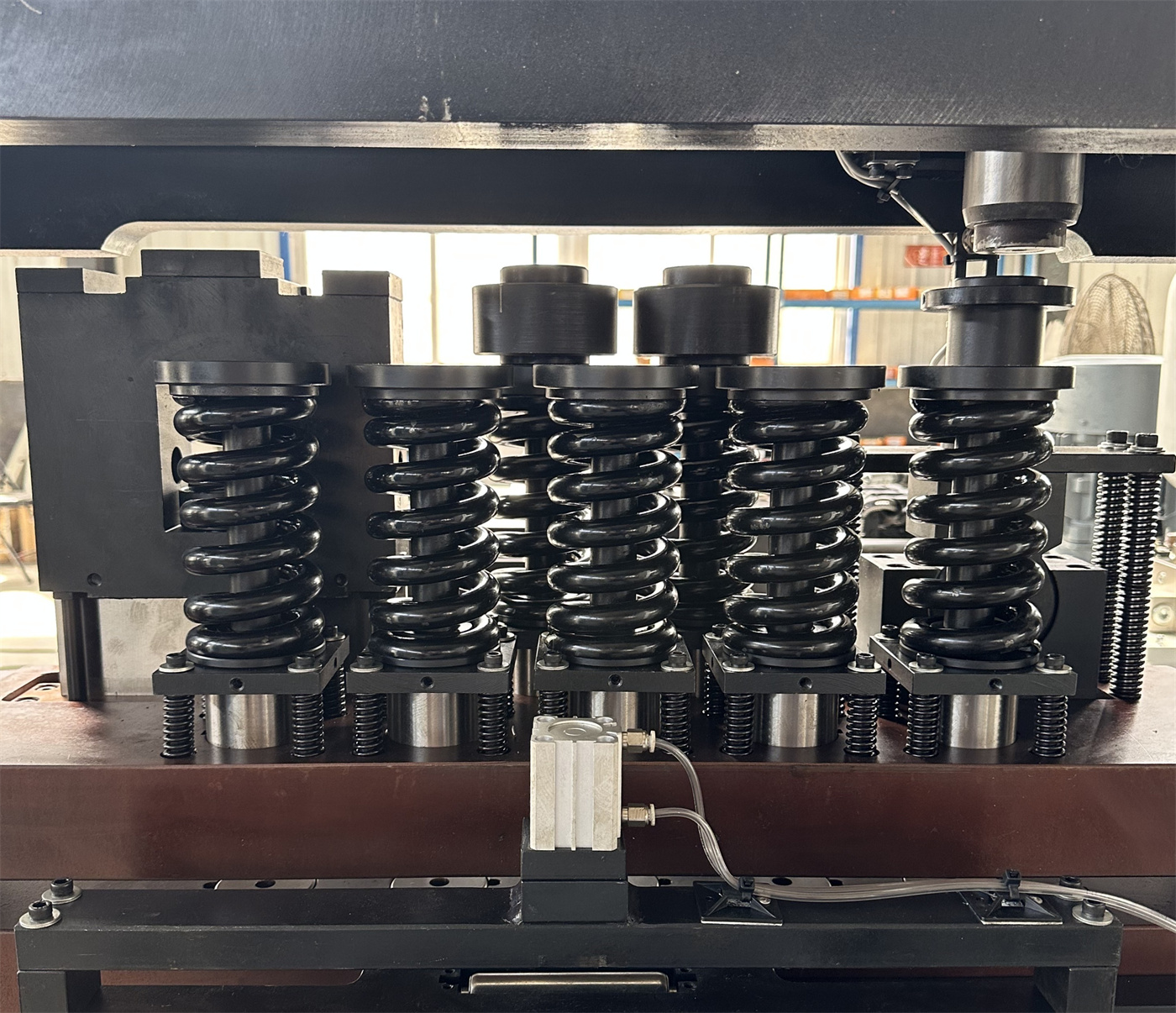

In terms of precision control, the equipment is equipped with an imported high-end CNC system, supporting the direct import of various 3D drawings and automatic generation of processing programs. Combined with a double-clamp design and high-precision displacement sensor, the positioning accuracy reaches ±0.05mm, completely eliminating the error problem of traditional manual marking and positioning. The shearing unit adopts an integral shear blade with high pressure, which can complete the cutting of busbars in one step, improving processing precision, section perpendicularity and processing efficiency. It ensures flat, burr-free and non-deformed shear ports, and no indentation on the workpiece surface after punching, effectively avoiding electrical safety hazards caused by poor contact during busbar assembly, and reducing the product scrap rate from 8%-10% of traditional equipment to below 1%.

In terms of environmental protection and stability, the GJCNC-BP-60 adopts a new energy-saving hydraulic system, reducing energy consumption by 30% compared with traditional equipment, and controlling operating noise below 70 decibels. Equipped with an air-cooled radiator, it ensures long-term continuous and stable operation of the equipment. The frame is welded with high-quality medium and thick steel plates, and after precision processing and aging treatment, the precision does not decay after long-term use, fully adapting to high-intensity and high-load production scenarios.

Humanized Design, Adapting to Diverse Application Scenarios

The GJCNC-BP-60 balances operational convenience and scenario adaptability. It is equipped with a touch-screen visual operation interface that displays processing parameters graphically. Workers can master the operation proficiently after short-term training without professional programming skills, greatly reducing human training costs. The equipment is built with a power-off memory function, which can automatically retain processing parameters for subsequent processing after midway shutdown. The automatic braking device effectively prevents reverse movement when stopping, further improving operational safety.

This equipment can accurately process copper and aluminum busbars of different specifications, and is widely used in the production and manufacturing of electrical equipment such as high and low voltage switchgear, distribution boxes, transformers and bus ducts. It perfectly meets the needs of high-end equipment manufacturing such as new energy power stations, rail transit and smart grid construction. Whether for mass standardized production or personalized custom processing, the GJCNC-BP-60 can help enterprises enhance their core competitiveness with flexible process configuration and stable performance output.

【放视频】

Dual Guarantee of Quality and Service, Empowering Efficient Production

Relying on Shandong Gaoji’s perfect production system and service network, the GJCNC-BP-60 strictly complies with the ISO9001 quality management standard. From parts procurement to finished product delivery, it undergoes multiple high-precision testing procedures to ensure the reliability and stability of each equipment. The company has a first-class after-sales service team, providing “lifetime technical consultation” services. The professional technical team responds quickly 24 hours a day, offering customers full-process service support including installation and commissioning, operation training and fault maintenance, completely solving the worries of enterprises.

A relevant person in charge of Shandong Gaoji said that the launch of the GJCNC-BP-60 CNC Busbar Punching and Shearing Machine is an important achievement of the company’s technological innovation-driven industrial upgrading. In the future, Shandong Gaoji will continue to focus on the technical pain points and demand upgrades in the electrical processing field, deepen the R&D of automated and intelligent equipment, and continuously launch more competitive products to inject strong momentum into the high-quality development of China’s electrical manufacturing industry.

At present, the GJCNC-BP-60 CNC Busbar Punching and Shearing Machine has been officially put on the market. We welcome customers from all walks of life to visit and negotiate, and work together to usher in a new era of efficient, precise and green processing.

Post time: Jan-21-2026