China Wholesale Copper Busbar Servo Bending Quotes - Chinese Professional China Autoamtic Busbar Processing Machine with Punch Shear and Bend – Gaoji

China Wholesale Copper Busbar Servo Bending Quotes - Chinese Professional China Autoamtic Busbar Processing Machine with Punch Shear and Bend – Gaoji Detail:

We’re also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Chinese Professional China Autoamtic Busbar Processing Machine with Punch Shear and Bend, With advantage of industry management, the firm has generally been committed to supporting prospects to become the industry leader in their respective industries.

We’re also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for China Busbar Machine for Copper Tube, CNC Busbar Machine for Copper Rod, Company name, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

Product Description

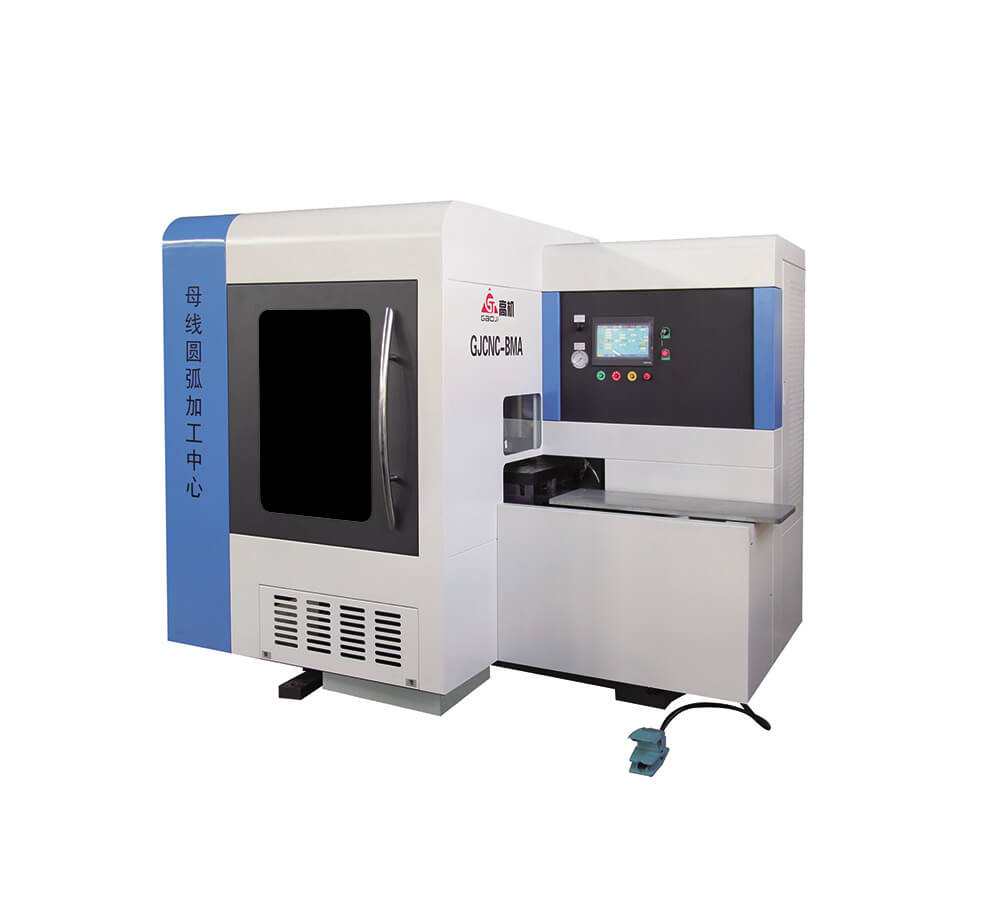

BM603-S-3 Series are multifunction busbar processing machine designed by our company. This equipment could do punching, shearing and bending all at the same time, and specially designed for large size busbar processing.

Advantage

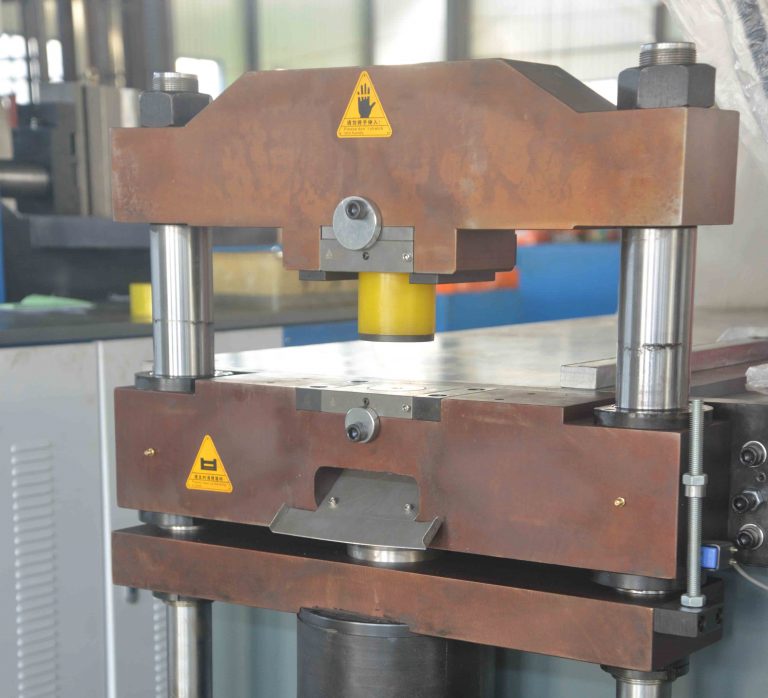

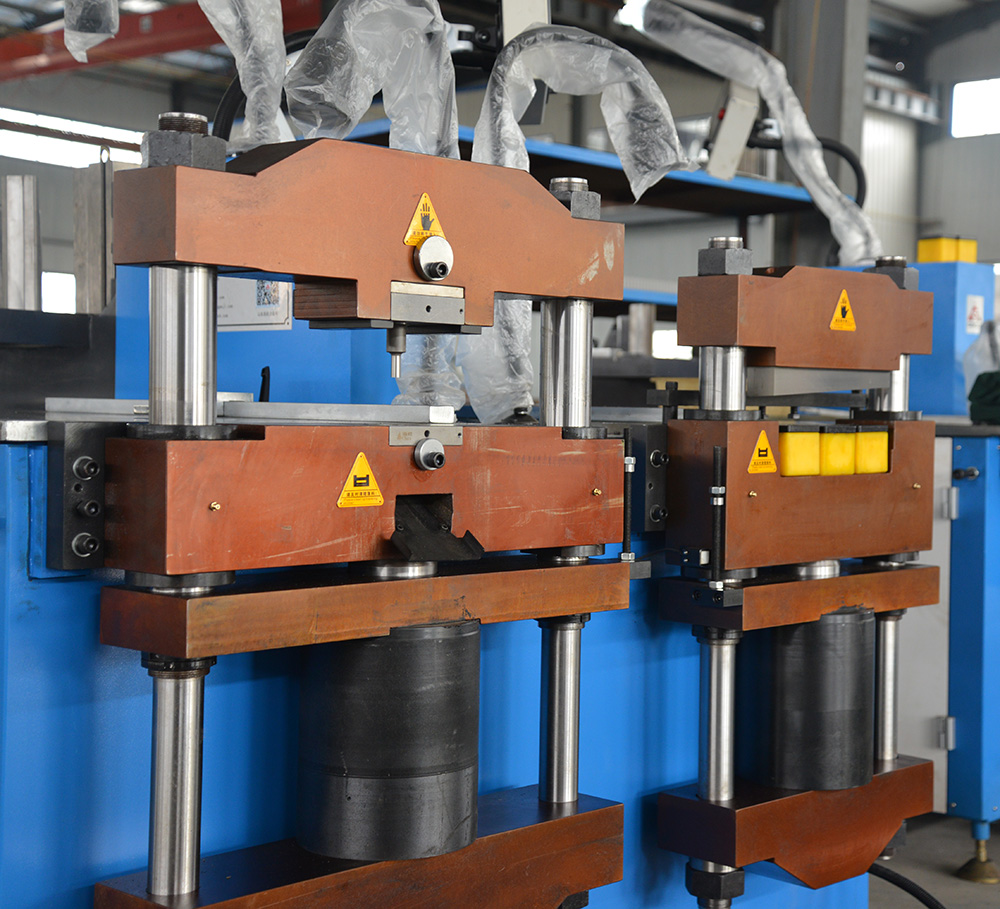

The punching unit adopt column frame, bear reasonable force, can effectively ensure long-term use without deformation. Punching die instal hole was processed by numerical control machine which will ensure high precision and long life, and a lot of process such like round hole, long round hole, square hole, double hole punching or embossing could be completed by changing the die.

The shearing unit also adopt column frame that will provide more power for the knife, the upper and lower knife was installed vertical parallelly, the single shearing mode ensure the kerf smooth with no waste.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

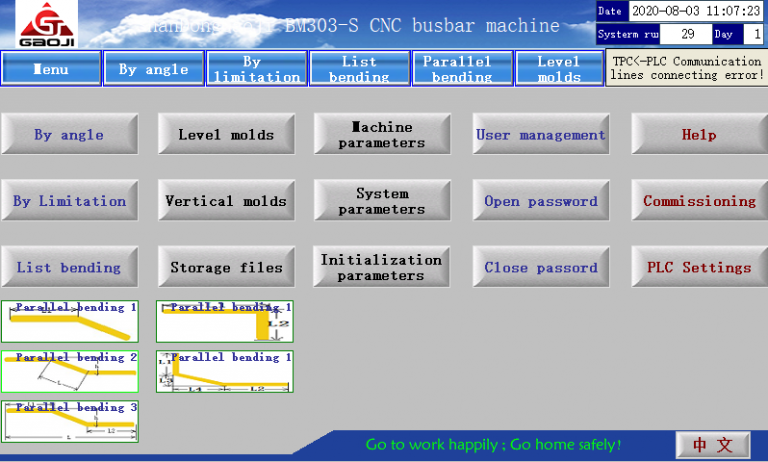

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

We’re also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Chinese Professional China Autoamtic Busbar Processing Machine with Punch Shear and Bend, With advantage of industry management, the firm has generally been committed to supporting prospects to become the industry leader in their respective industries.

Chinese Professional China Busbar Machine for Copper Tube, CNC Busbar Machine for Copper Rod, Company name, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for China Wholesale Copper Busbar Servo Bending Quotes - Chinese Professional China Autoamtic Busbar Processing Machine with Punch Shear and Bend – Gaoji, The product will supply to all over the world, such as: Nepal, Liverpool, Barcelona, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will be more conveniently to service our customers.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!