Featured Products

-

High Precision CNC Busbar Bending Machine Custom Metal Busbar Cutting and Bending Tool GJCNC-BB-S from Shandong Gaoji (SDGJ)

Model: GJCNC-BB-S

Function: Busbar level, vertical, twist bending

Character: Servo control system, high efficiently and accurately.

Output force: 350 kn

Material size:

Level bending 15*200 mm

Vertical bending 15*120 mm

-

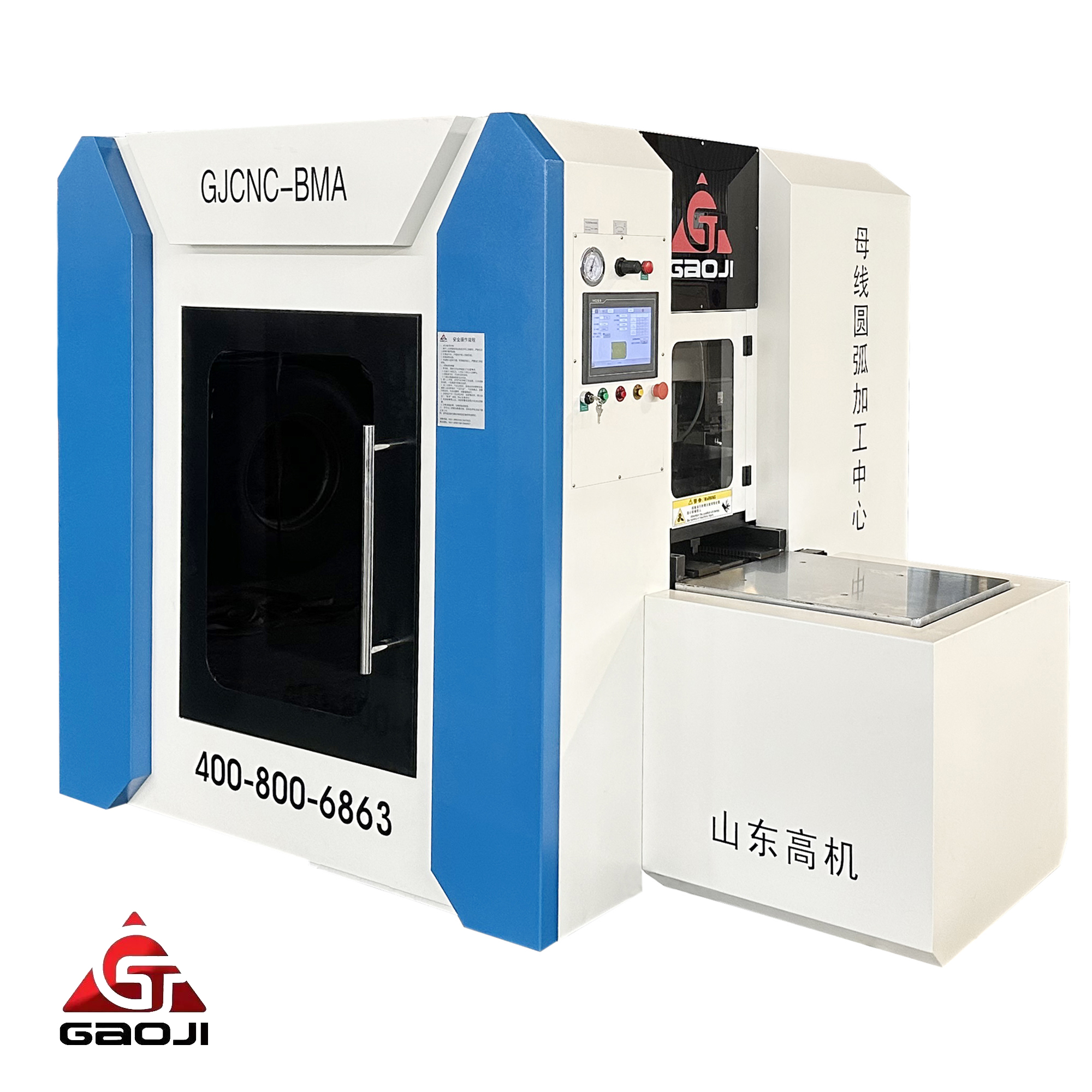

Factory Selling CNC Automatic High Effiency Arc Machining Center (Chamfering Machine) for Copper Busbar

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

China Cheap price Combined Busbar Bending Cutting Punching Machine

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

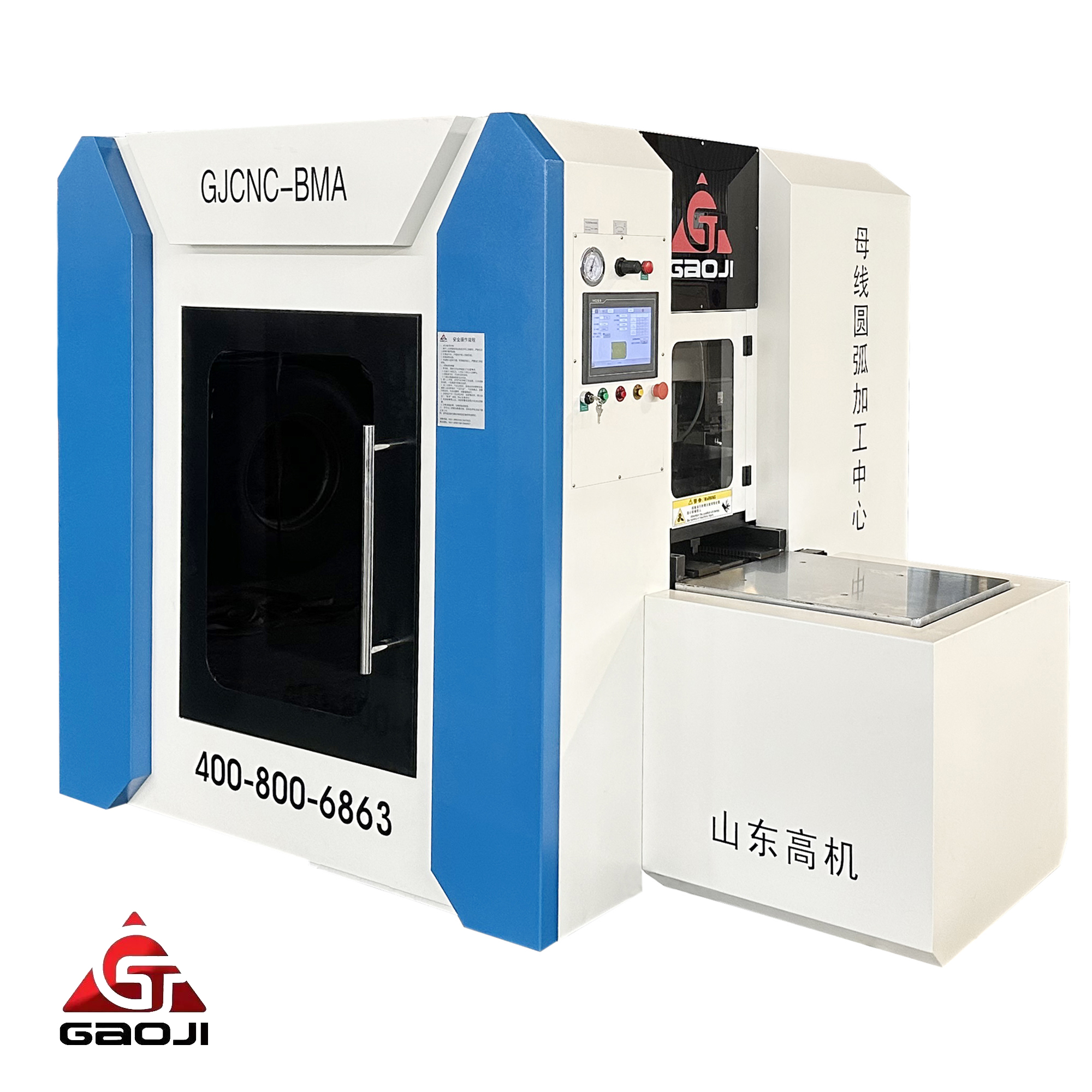

8 Years Exporter China Customized Tin Plated Brass Copper Busbar

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

Europe style for Three-in-One Multifunction Copper or Aluminum Worker Bus Bar Processing Machine for Busbar Processing Busbar Machine

Model: GJBM303-S-3-8P

Function: PLC assist busbar punching, shearing, level bending, vertical bending, twist bending.

Character: 3 unit could work at the same time. Punching unit have 8 punching dies position. Auto-calculate material length before bending process.

Output force:

Punching unit 350 kn

Shearing unit 350 kn

Bending unit 350 kn

Material size: 15*160 mm

-

Quality Inspection for Most Popular Punching, Shearing and Bending Busbar Machine

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

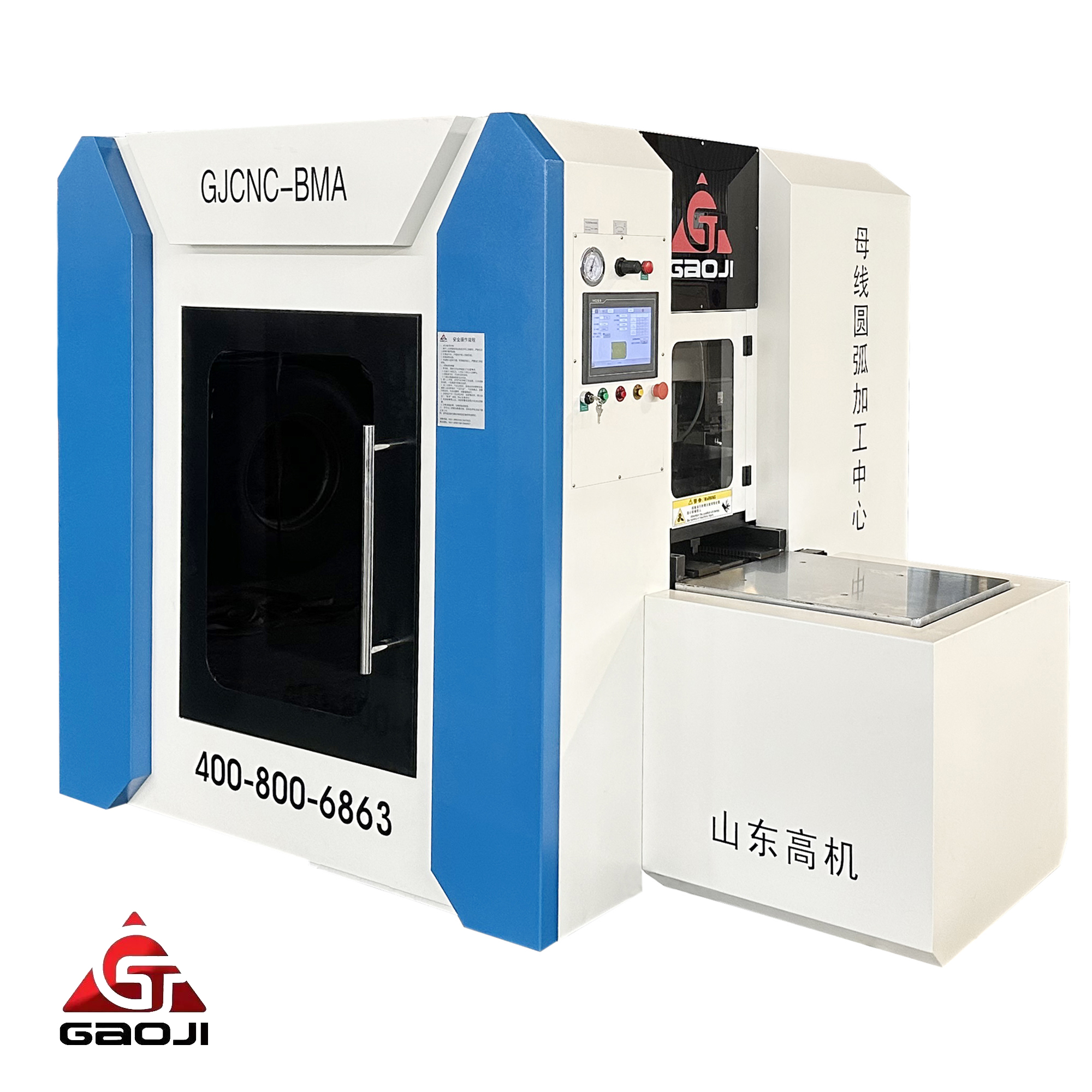

Factory supplied Copper Busbar Copper Block Premium Copper Bronze Support Customization

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

China Cheap price Heavy Duty Multifunction Busbar Bender for Sale

Model: GJBM303-S-3-8P

Function: PLC assist busbar punching, shearing, level bending, vertical bending, twist bending.

Character: 3 unit could work at the same time. Punching unit have 8 punching dies position. Auto-calculate material length before bending process.

Output force:

Punching unit 350 kn

Shearing unit 350 kn

Bending unit 350 kn

Material size: 15*160 mm

-

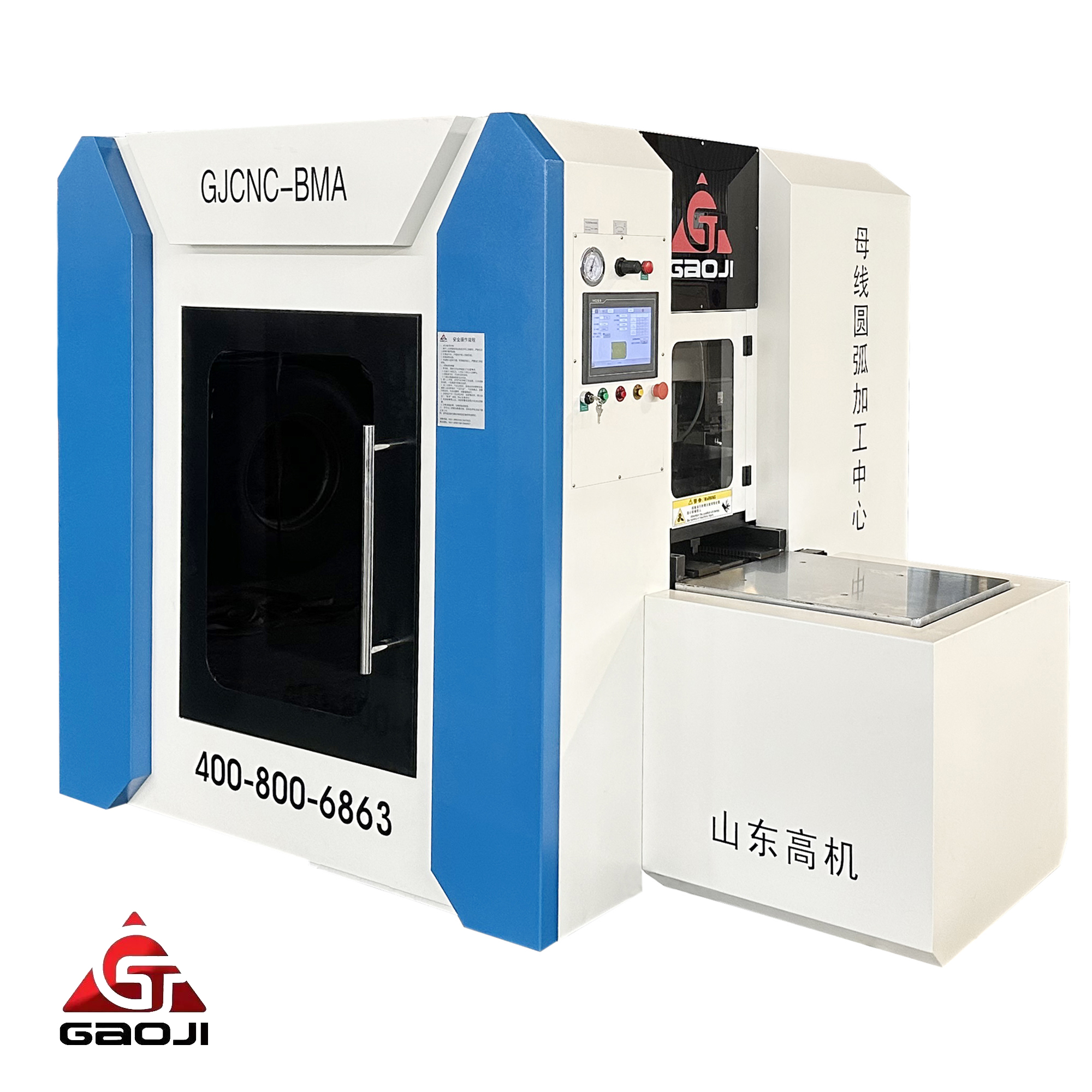

High reputation Bus Arc Machining Center (Chamfering Machine)

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

China Factory for Hydraulic Bus Bar Machine for Copper Aluminum Cutting Machine 3 in 1 CNC Busbar Cutting Punching Bending Machine

Model: GJCNC-BB-S

Function: Busbar level, vertical, twist bending

Character: Servo control system, high efficiently and accurately.

Output force: 350 kn

Material size:

Level bending 15*200 mm

Vertical bending 15*120 mm

-

2025 High Precision CNC Busbar Bending Machine Custom Metal Busbar Bending Tool GJCNC-BB-S From Shandong Gaoji (SDGJ)

Model: GJCNC-BB-S

Function: Busbar level, vertical, twist bending

Character: Servo control system, high efficiently and accurately.

Output force: 350 kn

Material size:

Level bending 15*200 mm

Vertical bending 15*120 mm

-

Professional Efficient Busbar Chamfering Machine Big Fillet Milling Equipment for Busbar Fillet Processing

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm