Featured Products

-

2019 China New Design Multifunction Busbar Processing Shearing Punching Bending Machine (For Larger Busbar)

Model: GJBM303-S-3-8P

Function: PLC assist busbar punching, shearing, level bending, vertical bending, twist bending.

Character: 3 unit could work at the same time. Punching unit have 8 punching dies position. Auto-calculate material length before bending process.

Output force:

Punching unit 350 kn

Shearing unit 350 kn

Bending unit 350 kn

Material size: 15*160 mm

-

Supply OEM/ODM Custom Square Electricity Copper Busbar

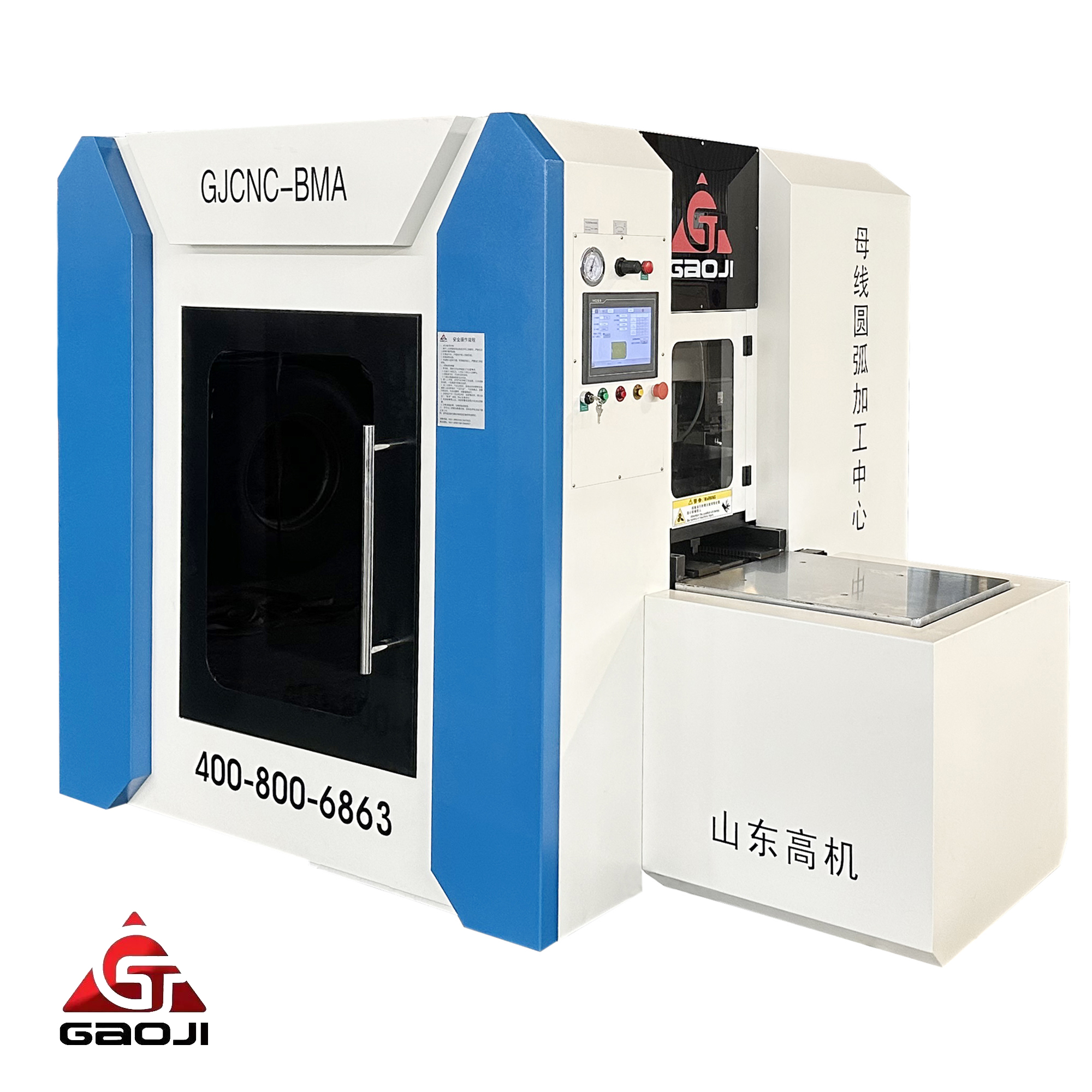

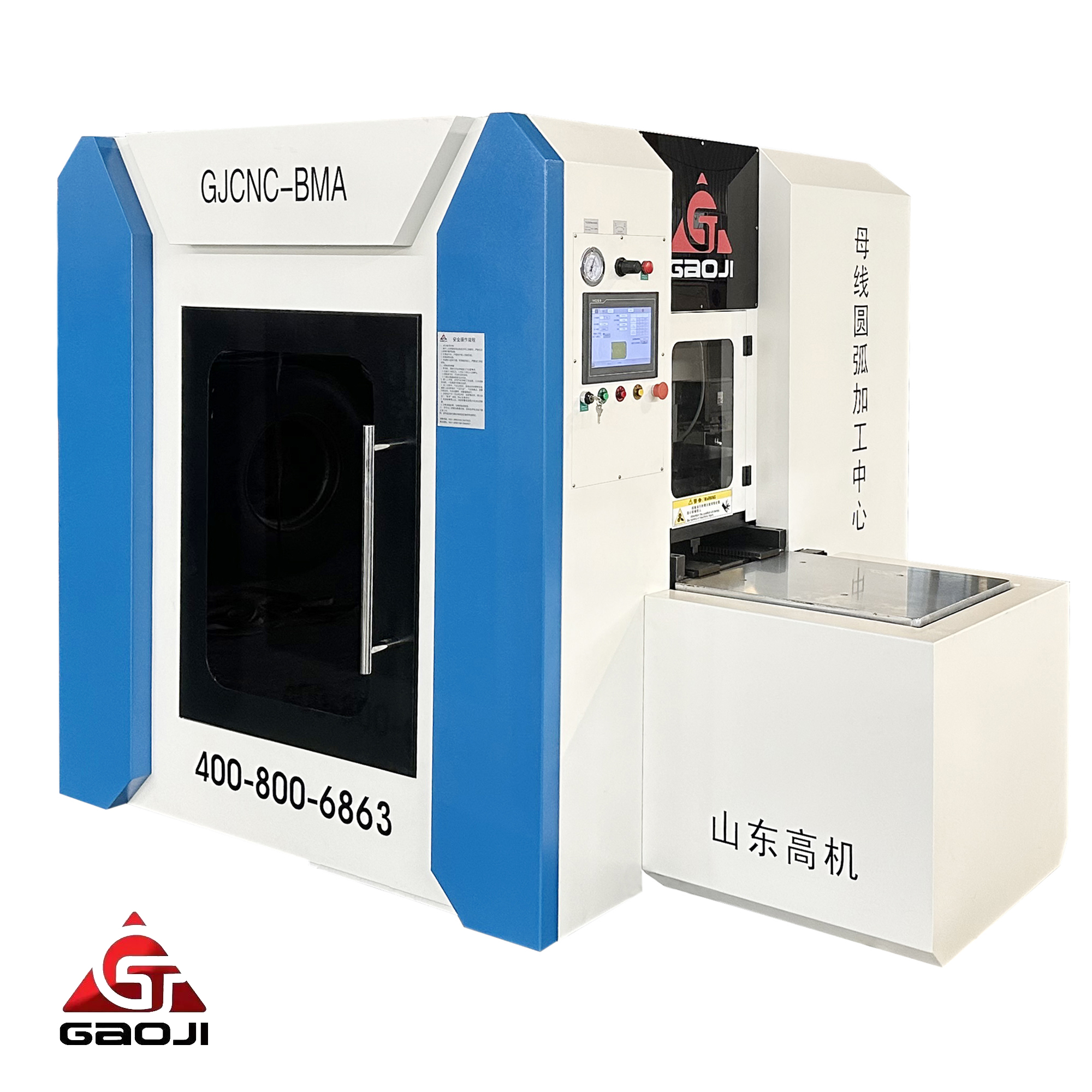

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

Chinese Professional Metal Folding and Welding Custom Equipment Hardware Factory Price with Rod and Nut

1. Ring cabinet machining center can automatically complete the copper bar three-dimensional space multi-dimensional Angle of automatic bending, CNC punching, one-time flattening, chamfering shear and other processing technology;

2. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

3. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

-

Best-Selling Hot Sale High Efficiency Automatic CNC Busbar Bending Machine

Model: GJBM303-S-3-8P

Function: PLC assist busbar punching, shearing, level bending, vertical bending, twist bending.

Character: 3 unit could work at the same time. Punching unit have 8 punching dies position. Auto-calculate material length before bending process.

Output force:

Punching unit 350 kn

Shearing unit 350 kn

Bending unit 350 kn

Material size: 15*160 mm

-

Professional Efficient Busbar Chamfering Machine Big Fillet Milling Equipment for Busbar Fillet Processing GJCNC-BMA

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

CNC Busbar Processing Machinery Hydraulic Copper Bar Punching Bending Shearing Machine

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

Cheap Price Copper Durable Fast Aluminum Bar Shearing and Punching Machine for Sandwich Busbar

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

Hot New Products 503esk Factory Directly Supply Busbar Punching Bending Cutting Machine for Transformer

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

Personlized Products OEM High Precision Aluminum Alloy CNC Milling Turning Guide Rod Plate Holder

1. Ring cabinet machining center can automatically complete the copper bar three-dimensional space multi-dimensional Angle of automatic bending, CNC punching, one-time flattening, chamfering shear and other processing technology;

2. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

3. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

-

2019 Latest Design Steel Cable Drag Chains Cable Carrier

Model: GJCNC-BB-S

Function: Busbar level, vertical, twist bending

Character: Servo control system, high efficiently and accurately.

Output force: 350 kn

Material size:

Level bending 15*200 mm

Vertical bending 15*120 mm

-

Fast delivery Premium Copper Line Set Bender Kit for Air Conditioners

1. Ring cabinet machining center can automatically complete the copper bar three-dimensional space multi-dimensional Angle of automatic bending, CNC punching, one-time flattening, chamfering shear and other processing technology;

2. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

3. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

-

Professional Efficient Busbar Chamfering Machine Big Fillet Milling Equipment for Busbar Fillet Processing GJCNC-BMA from Shandong Gaoji

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm