Featured Products

-

factory Outlets for GJCNC-BB-S Good Service Energy Saving Durable Equipment CNC Busbar Machinery

Model: GJCNC-BB-S

Function: Busbar level, vertical, twist bending

Character: Servo control system, high efficiently and accurately.

Output force: 350 kn

Material size:

Level bending 15*200 mm

Vertical bending 15*120 mm

-

Discount Price High Quality Hydraulic Busbar Punching Cutting Bending Machine

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

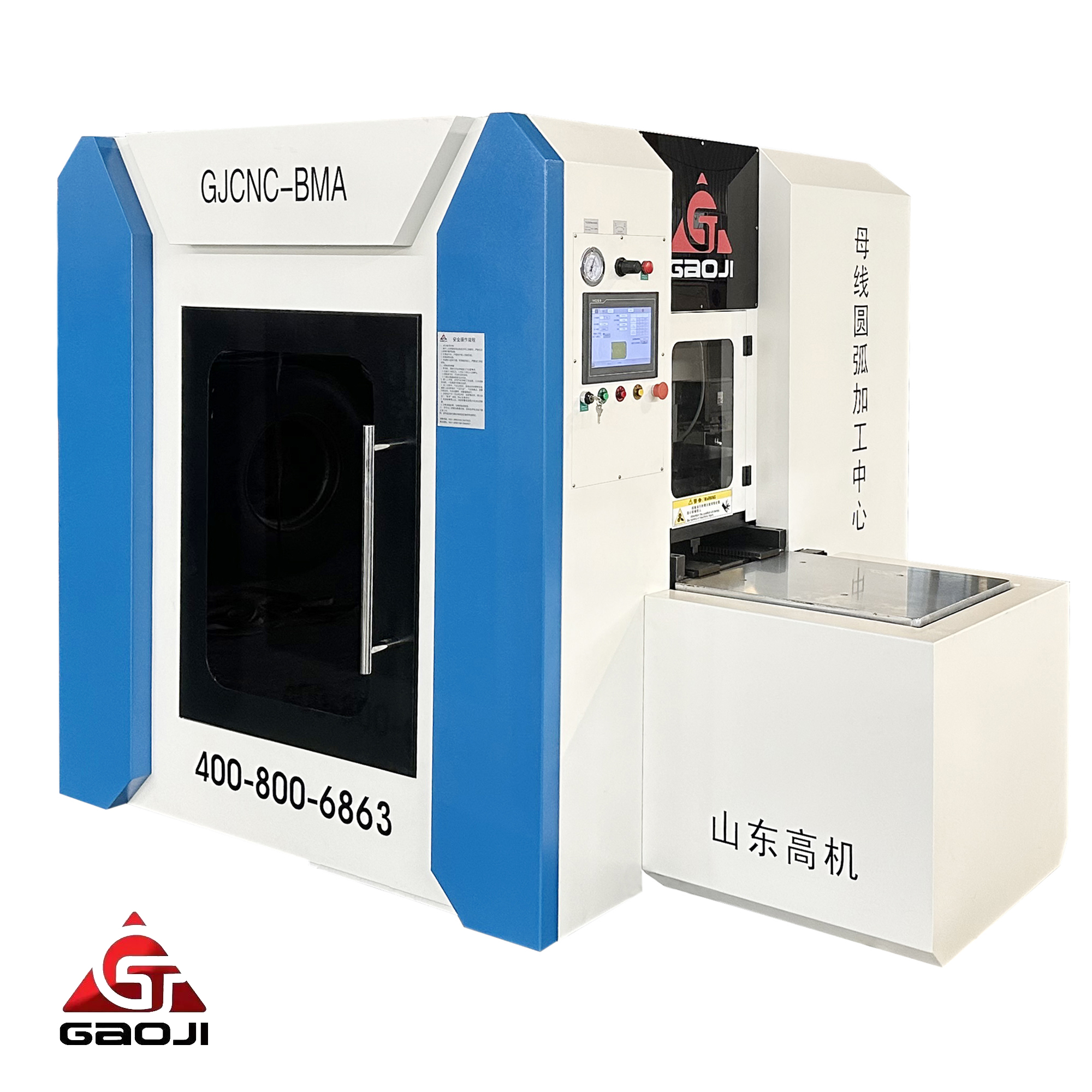

OEM China Premium Copper Busbar Supplier with Competitive Factory Pricing

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

Best Price on Busbar Press Punching Cutting Bending Machine Copper Busbar Processing Machine BP60

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

OEM Customized CNC-BMA Bus Arc Chamfering Milling Machine for Copper

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~160 mm

Min Length 120 mm

Thickness 3~15 mm

-

Cheapest Factory ISO 9001: 2015 Approved CNC Servo Electric New High Quality Sheet Stainless Steel Bending GJCNC-BB-S

Model: GJCNC-BB-S

Function: Busbar level, vertical, twist bending

Character: Servo control system, high efficiently and accurately.

Output force: 350 kn

Material size:

Level bending 15*200 mm

Vertical bending 15*120 mm

-

Factory made hot-sale Busbar Machine for Transformer Manufacturer Copper Punching Cutting Machine BP60

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

2019 High quality Cheap Price Good Quality Copper Arc Milling Machine GJBMA

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~160 mm

Min Length 120 mm

Thickness 3~15 mm

-

Manufacturer of Busbar Bending and Punching Busbar Shear Machine 3-in-1 Multi-Function CNC Busbar Processing Machine

Model: GJBM303-S-3-8P

Function: PLC assist busbar punching, shearing, level bending, vertical bending, twist bending.

Character: 3 unit could work at the same time. Punching unit have 8 punching dies position. Auto-calculate material length before bending process.

Output force:

Punching unit 350 kn

Shearing unit 350 kn

Bending unit 350 kn

Material size: 15*160 mm

-

Professional Efficient Busbar Chamfering Machine Big Fillet Milling Equipment for Busbar Fillet Processing Sdgj GJCNC-BMA

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~160 mm

Min Length 120 mm

Thickness 3~15 mm

-

OEM China CNC Punching-Cropping Machine for Busbar (Punch and Shear) BP60 from Sdgj

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

Discount wholesale CNC Busbar Cutting Punching Bending Machine 3in1-CNC Copper Processing for Copper

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm