As a key enterprise in the industrial machinery field rooted in Shandong and serving the world, Shandong Gaoji Industrial Machinery Co., Ltd. has always taken “supporting the high-quality development of the manufacturing industry” as its mission. It is deeply engaged in the R&D and production of supporting processing equipment for power transmission, and has accumulated profound experience especially in the technical optimization and global service of busbar processing machines, the core equipment for busbar processing. With the rapid development of global industries such as new energy, high-end equipment manufacturing, and data centers, the market demand for busbars (key carriers for power transmission) in terms of processing precision, efficiency, and customization continues to rise. Relying on the mature technology and stable performance of its classic busbar processing machine series, as well as its ability to adapt to busbar processing scenarios in different regions around the world, Shandong Gaoji provides efficient and reliable busbar processing solutions for industrial enterprises at home and abroad, helping to promote the green and efficient transformation of the global power supporting industry.

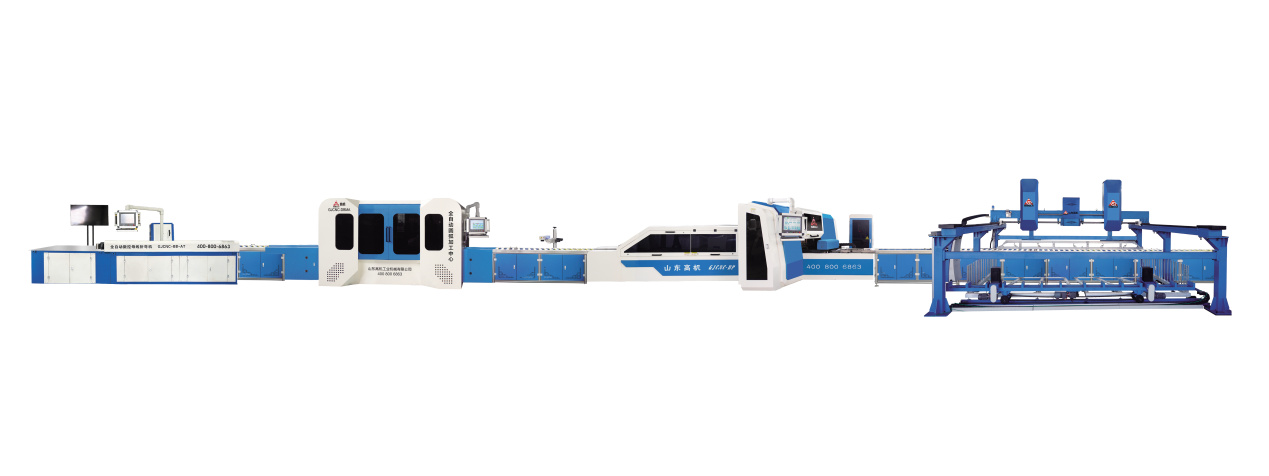

Full-Automatic Busbar Intelligent Production Line

Fully-auto Intelligent Busbar Warehouse

Classic Busbar Processing Machine Series: “Reliable Tools” for Busbar Processing, Adapting to Diverse Busbar Materials and Global Scenarios

As the “nerve center” of the power system, the processing quality of busbars is directly related to the safety and stability of power transmission. Based on global industrial needs, Shandong Gaoji has developed a full range of classic busbar processing machine series to meet the busbar forming needs of enterprises in different countries and regions for processing common busbar materials such as copper and aluminum, as well as adapting to diverse scenarios including new energy vehicle industrial parks, chemical industrial parks, heavy machinery manufacturing bases, and data centers. This series covers the entire process of shearing, punching, bending, and combined processing, and has become a preferred equipment for busbar processing enterprises around the world due to its mature technology and stable performance.

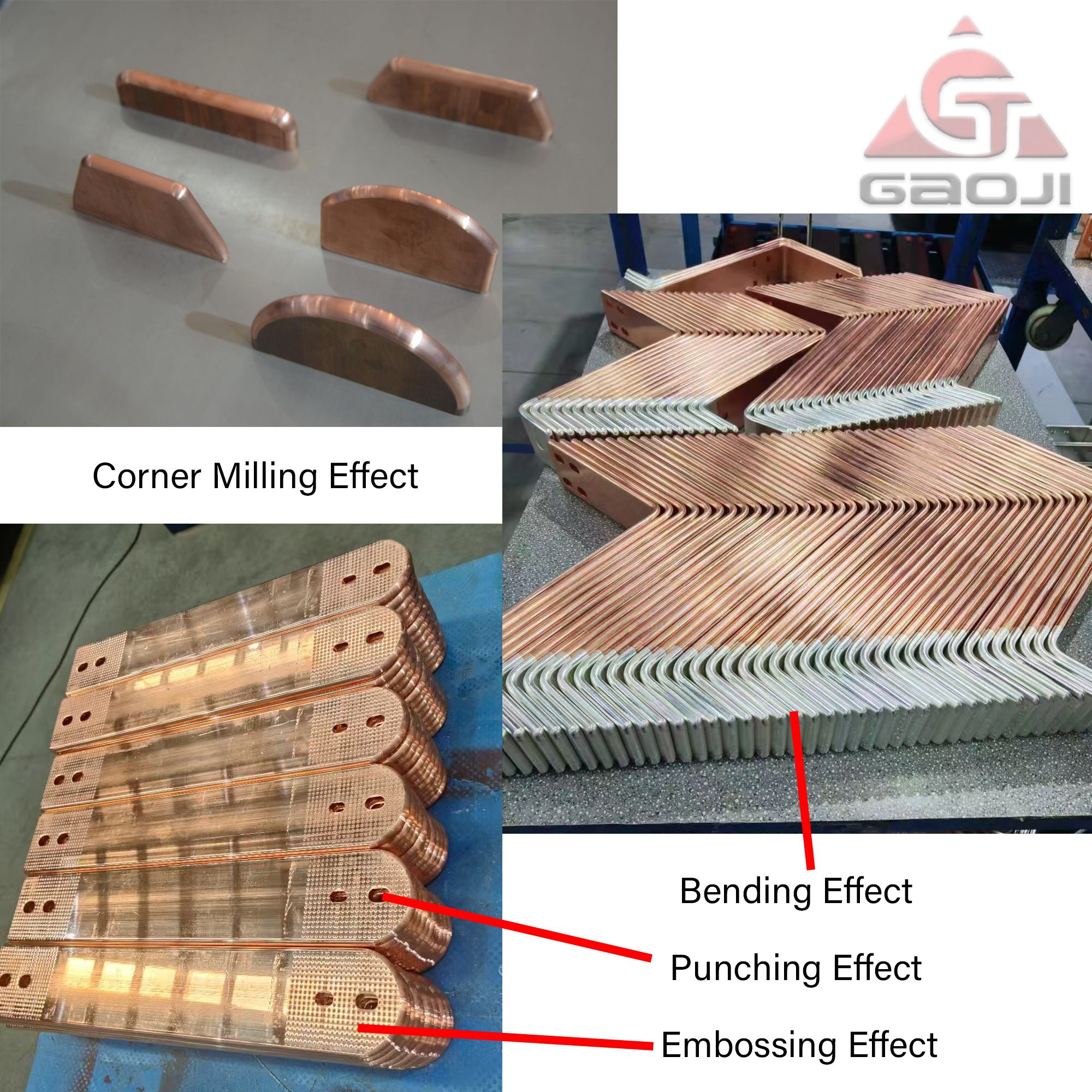

1. Multi-Material Universal Processing Capability

Aiming at the characteristics of copper busbars and aluminum busbars commonly used in the global market, Shandong Gaoji’s classic busbar processing machines have formed a mature processing parameter system through long-term technical optimization. When processing copper busbars, the flatness error of the cutting edge can be stably controlled within ≤ 0.05mm, effectively avoiding the impact of burrs on electrical conductivity; when processing aluminum busbars, the bending springback rate is accurately controlled within 1%, perfectly matching the assembly size requirements of various power equipment. It meets the processing standards of busbars made of different materials and adapts to the power equipment production specifications of most countries in the world.

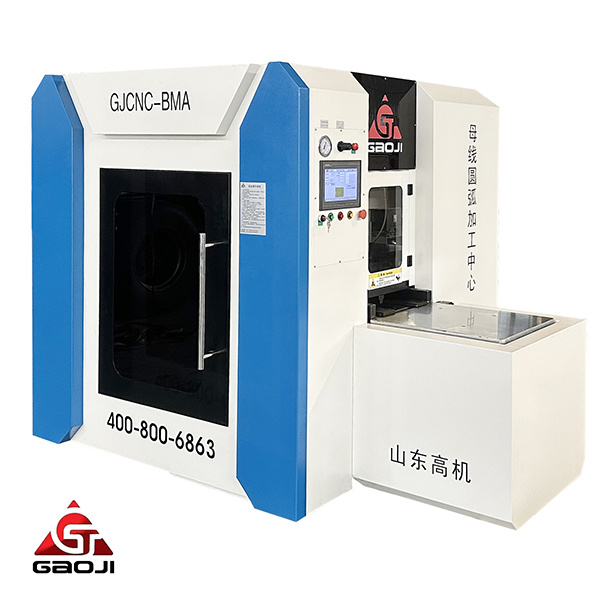

CNC Busbar Punching and Shearing Machine

CNC busbar servo bending machine

Bus Arc Machining Center (Chamfering Machine)

2. Processing Advantages for High-Current Busbars

To meet the processing needs of large-section busbars required by heavy industry and metallurgical industries, the classic series of busbar processing machines can stably support the processing of busbars with a thickness of ≤ 12mm and a width of ≤ 200mm. The equipment adopts an integrated machine body design and a multi-station collaborative structure, which can easily complete the complex forming process of high-current busbars, solving the problems of low processing efficiency and insufficient precision of power transmission components for heavy equipment, and is widely suitable for busbar processing needs in the global high-end manufacturing field.

3. Flexible Adaptation to Customization Needs

Facing the diverse busbar specification requirements in scenarios such as global data centers and new energy projects, Shandong Gaoji’s classic busbar processing machines have excellent flexible adjustment capabilities. The equipment supports direct import of CAD drawings, can quickly generate processing paths, and can switch the processing programs of busbars of different specifications without complex debugging. Verified by the market, its single-batch processing efficiency is more than 3 times higher than that of traditional equipment, which can efficiently respond to the customized busbar processing orders of global customers and adapt to the project schedule requirements in different regions.

4. Stable Performance in Safety and Energy Conservation

Shandong Gaoji’s classic busbar processing machines have taken into account the needs of global enterprises for safe production and cost control since the initial design stage. The equipment is equipped with an energy-saving motor, and its normal operation energy consumption is 15% lower than that of similar products in the industry, which can help enterprises reduce energy expenditure in long-term use; at the same time, it is equipped with an infrared protection device that meets international safety standards, which automatically stops when the human body is close to the processing area to ensure the safety of operators and meet the industrial safety specifications of most countries and regions in the world.

With stable performance and reliable quality, Shandong Gaoji’s classic busbar processing machines have served customers in many countries and regions around the world, including new energy enterprises in Southeast Asia, heavy industry supporting manufacturers in Europe, and data center equipment suppliers in South America. At the same time, in the domestic market, they also deeply serve key customers such as supporting manufacturers of Shandong Heavy Industry Group and Qingdao Port power equipment processing enterprises, becoming a “reliable partner” in the field of busbar processing at home and abroad.

Display of Processing Effects of Busbar Processing Equipment

Global Service System: Providing Full-Cycle Support for Foreign Customers

Shandong Gaoji is well aware that stable equipment performance and timely service support are crucial for global customers to choose equipment. For this reason, the company has established a global service system to provide full-cycle support for foreign customers from equipment selection to after-sales maintenance:

1. Professional Selection Support

In response to the electrical standards and busbar processing requirements of different countries and regions, the company’s equipment is equipped with a bilingual operating system. Meanwhile, in terms of customer service, it can provide customers with customized equipment selection solutions through online communication, video connection and other methods, so as to ensure that the equipment accurately matches the customers’ production scenarios.

2. Efficient Delivery and Installation

To ensure that the equipment can be put into production as soon as possible after it is delivered to the customer’s site on time and safely, we provide customers with remote installation guidance and, when necessary, dispatch professional engineers to the site for installation and commissioning, so as to guarantee the rapid commissioning of the equipment into production.

3. Full-Cycle Training and Maintenance

It provides multilingual training services for customers on equipment operation and daily maintenance to help customers quickly master the equipment use skills; a 24-hour online after-sales response mechanism is established to provide timely technical support and spare parts supply for equipment failure problems, ensuring that the customer’s production is not affected.

Adhering to Quality to Help the Development of the Global Power Supporting Industry

For a long time, Shandong Gaoji has been focusing on the technical optimization and quality improvement of classic busbar processing machines. Through continuous improvement of production processes and strict quality inspection control, it ensures that each piece of equipment has stable and reliable performance. In the future, the company will continue to rely on mature technical accumulation, combine with changes in global market demand, carry out detailed optimization and functional upgrading of classic busbar processing machines, further improve the versatility, energy conservation and safety of the equipment, and provide high-quality equipment and services for industrial enterprises in more countries and regions around the world, helping the high-quality development of the global power supporting industry.

For detailed information on classic busbar processing machine products, access to equipment parameter manuals, or inquiries about cooperation plans, you may visit the official website of Shandong Gaoji Industry Machinery Co., Ltd. at https://www.busbarmach.com/, or contact us via email at int@busbarmach.com or the international service hotline (+86-531-85669527).

Post time: Sep-26-2025