When you think about “electricity in your home/office,” the first things that come to mind are probably sockets, wires, and switches. But there’s a “behind-the-scenes giant” without which even the most advanced appliances would grind to a halt – that’s the **busbar**. And the tool that ensures busbars fit perfectly into circuits and transmit electricity stably? The **busbar processing machine**. Today, let’s take a closer look at this “power duo” and discover where they’re quietly hard at work!

First, let’s talk about the “electricity conveyor belt” – the busbar.

You can think of it as a “super main road” in a circuit: ordinary wires are like narrow alleys, only capable of carrying small amounts of current. But a busbar is a thick, structured “two-way eight-lane highway” that safely and efficiently distributes high currents from power plants and substations to factory workshops, office buildings, and even the distribution box in your home.

Its footprint is wider than you might imagine:

- In the distribution room of your residential complex’s basement, those rows of metal “long strips” are busbars distributing electricity to each building;

- Shopping malls’ central air conditioning, elevators, and lighting systems all rely on busbars to “get enough power” simultaneously, avoiding tripping or glitches;

- Factory production lines, hospital MRI machines, and data center servers – these “power-hungry giants” simply can’t function without busbars. After all, ordinary wires can’t handle such large currents; only busbars can keep things stable.

Next, let’s explore the busbar’s “exclusive tailor” – the busbar processing machine.

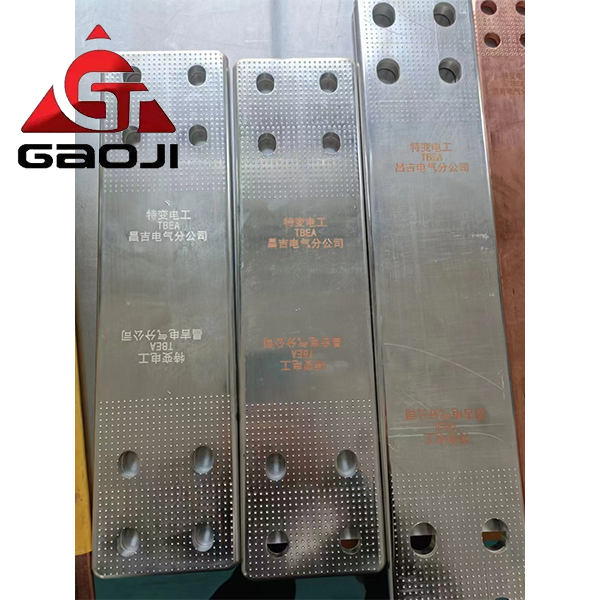

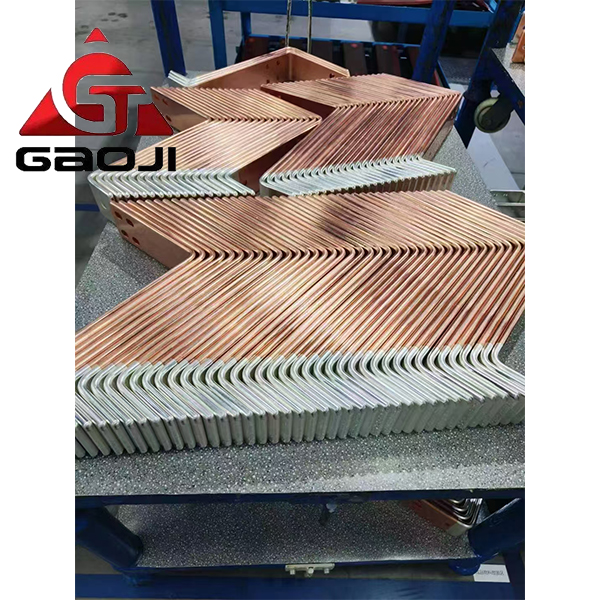

Busbars aren’t ready to use right out of the box: they need to be cut to the right length based on power distribution needs, bent at specific angles to avoid other equipment, and drilled with holes for easy assembly… This meticulous work is all handled by the busbar processing machine.

How important is it? Let’s take an example:

If you cut a busbar with a hand saw, the cut will be uneven. When assembling, this can lead to poor contact, which over time causes overheating and even fires. But with the cutting function of a busbar processing machine, the cut is smooth and neat, with an error of less than a millimeter.

Another example: in a hospital’s distribution room, space is tight and equipment is dense. Busbars need to be bent into “90-degree right angles” or “U-shaped bends.” Manual bending easily deforms the busbar and affects its conductivity. However, the bending function of a busbar processing machine can operate precisely according to design drawings, ensuring both safety and efficiency.

In fact, whether it’s the stable electricity supply in your home or the smooth operation of shopping malls, factories, and hospitals, none of it would be possible without the collaboration of busbars and busbar processing machines. They aren’t as “eye-catching” as mobile phones or appliances, but they are the most reliable “invisible heroes” in the power system. Next time you pass by a distribution room, take a moment to look – you might just catch a glimpse of this hardworking duo!

Post time: Nov-05-2025