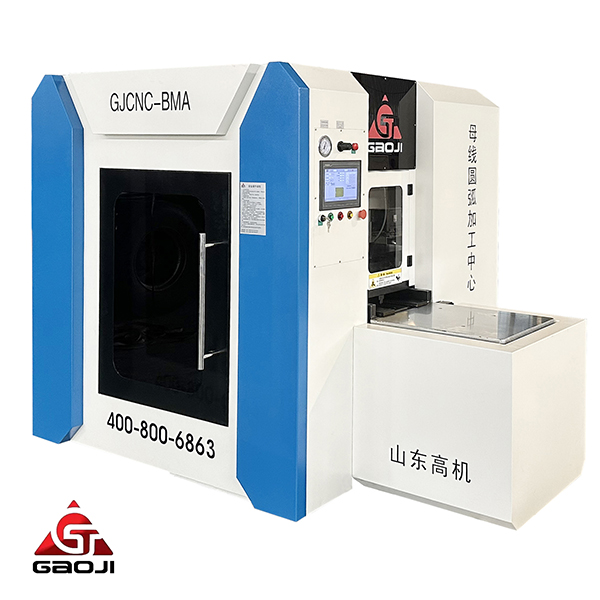

Professional Efficient Busbar Chamfering Machine Big Fillet Milling Equipment for Busbar Fillet Processing GJCNC-BMA

We pursue the administration tenet of "Quality is top-quality, Services is supreme, Popularity is first", and will sincerely create and share success with all clients for Well-designed Fillet De 100 Kg Cameroon, For anyone who is fascinated in any items, be sure to truly feel totally free to speak to us for further more details or be sure to deliver us email immediately, we will reply you in 24 hrs as well as the most effective quotation will probably be provided.

We pursue the administration tenet of "Quality is top-quality, Services is supreme, Popularity is first", and will sincerely create and share success with all clients for , Be sure to feel cost-free to send us your specifications and we will respond for you asap. We have got a specialist engineering team to serve for the every single detailed needs. Free samples may be sent for you personally personally to know far more facts. So that you can meet your desires, you should seriously feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Product Details

CNC busbar milling machine mainly functions in milling fillet and big fillet in the busbar. It automatically generates the program code and transmits the code to the equipment basing on the requirements on the busbar specification and the data input onto the display screen. It is easy to operate and can machine useful busbar arc with nice looking.

Advantage

This machine is used to carry out sectional arc machining for busbar heads with the H≤3-15mm, w≤140mm and L≥280mm.

The bar head will be machined to the shape with fixed structure.

The clamps adopt automatic centering technology to press the pressing head better onto the force bearing point.

A booster is used on the pressing head to secure the stability of workpiece, rendering a better machining surface effect.

World standard BT40 tool holder is used for easy blade replacement, fine rigidity and high accuracy.

This machine adopts high-precision ball screws and linear guides. Heavy-load large-size guide rails have been selected to offer better rigidity of the entire machine, lower the vibration and noise, improve the quality of workpiece and ensure high accuracy and efficiency.

Using components of domestic and world famous brands, this machine is of long service life and can guarantee high quality.

The program used in this machine is the embedded automatic graphics programming software developed by our company, realizing the automation in programming. The operator does not have to understand various codes, nor does he/she have to know how to operate the traditional machining center. The operator just has to enter several parameters by referring to the graphics, and the equipment will generate automatically the machine codes. It takes shorter time than manual programming and eliminates the potential of code error caused by manual programming.

Busbar machined in this machine is of fine look, without point discharge, narrowing the cabinet size to save space and remarkably reducing the consumption of copper.

We pursue the administration tenet of "Quality is top-quality, Services is supreme, Popularity is first", and will sincerely create and share success with all clients for Well-designed Fillet De 100 Kg Cameroon, For anyone who is fascinated in any items, be sure to truly feel totally free to speak to us for further more details or be sure to deliver us email immediately, we will reply you in 24 hrs as well as the most effective quotation will probably be provided.

Well-designed Bag and Plastic Bag, Be sure to feel cost-free to send us your specifications and we will respond for you asap. We have got a specialist engineering team to serve for the every single detailed needs. Free samples may be sent for you personally personally to know far more facts. So that you can meet your desires, you should seriously feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Configuration

| Dimension (mm) | Weight (kg) | Working Table Size (mm) | Air Source (Mpa) | Total Power (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Technical Parameters

| Moter Power (kw) | 7.5 | Servo Power (kw) | 2*1.3 | Max Torpue (N.m) | 62 |

| Tool Holder Model | BT40 | Tool Diameter (mm) | 100 | Speed of Spindle (RPM) | 1000 |

| Material Width (mm) | 30~140 | Min Material Length (mm) | 110 | Material Thickness (mm) | 3~15 |

| X-Axis Stoke (mm) | 250 | Y-Axis Stoke (mm) | 350 | Quick Position Speed (mm/min) | 1500 |

| Pitch of Ballscrew (mm) | 10 | Position Accuracy (mm) | 0.03 | Feeding Speed (mm/min) | 1200 |