China Wholesale Hydraulic Busbar Bending Cutting Punching Machines Factories - Multifunction busbar 3 in 1 processing machine BM603-S-3 – Gaoji

China Wholesale Hydraulic Busbar Bending Cutting Punching Machines Factories - Multifunction busbar 3 in 1 processing machine BM603-S-3 – Gaoji Detail:

Product Description

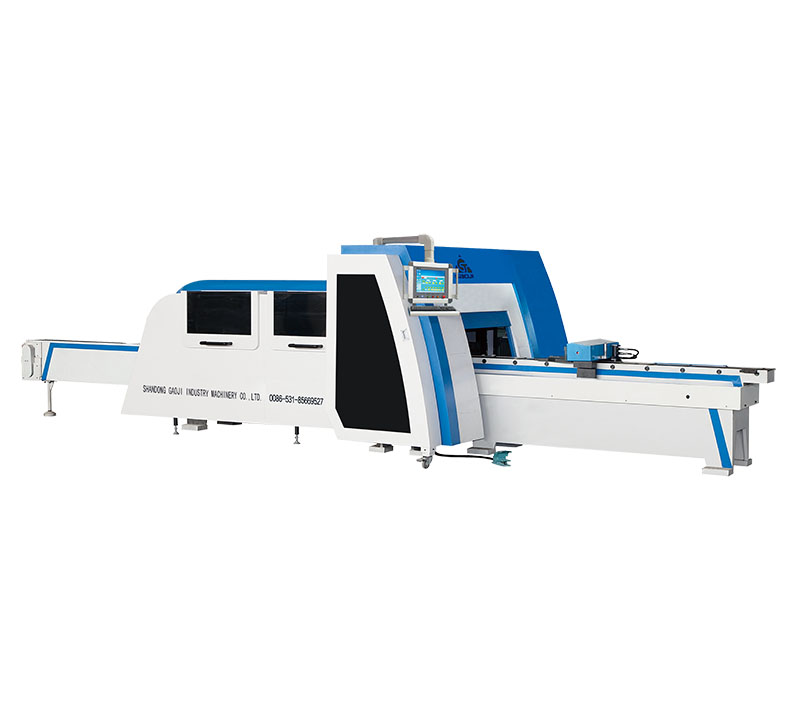

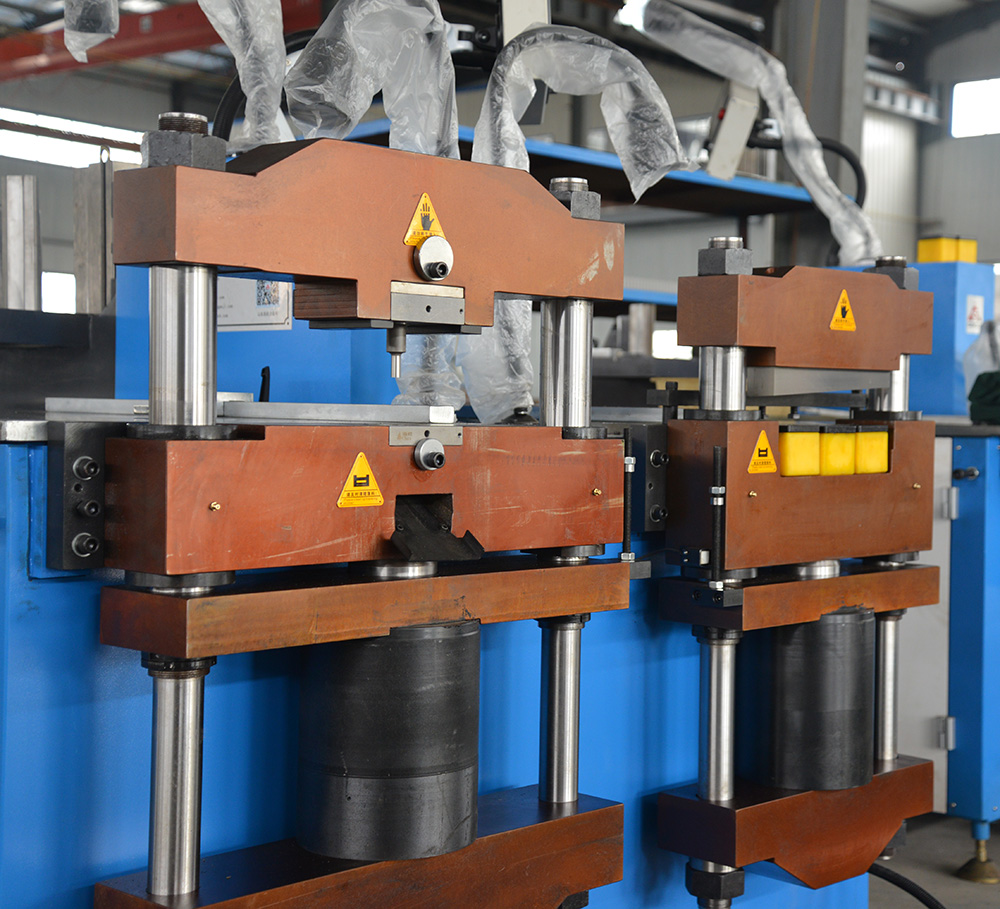

BM603-S-3 Series are multifunction busbar processing machine designed by our company. This equipment could do punching, shearing and bending all at the same time, and specially designed for large size busbar processing.

Advantage

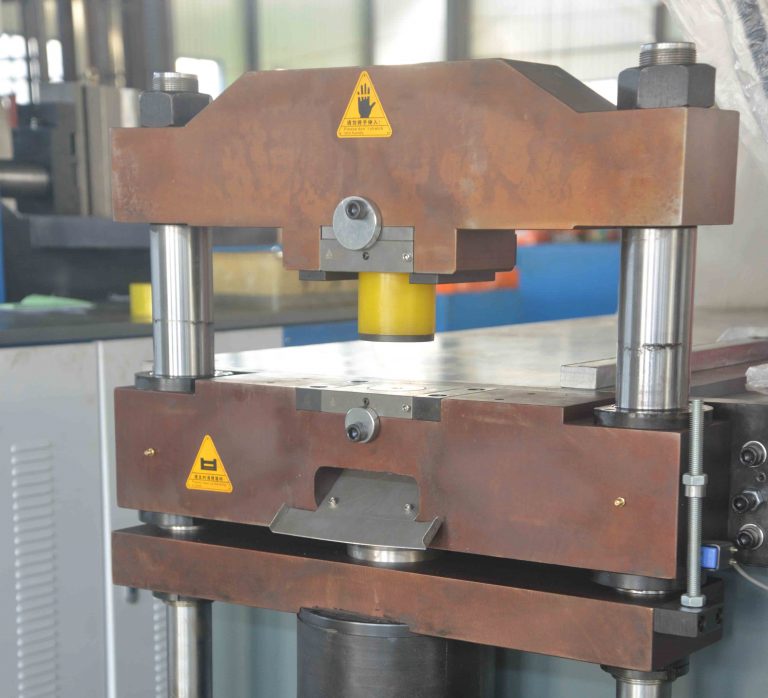

The punching unit adopt column frame, bear reasonable force, can effectively ensure long-term use without deformation. Punching die instal hole was processed by numerical control machine which will ensure high precision and long life, and a lot of process such like round hole, long round hole, square hole, double hole punching or embossing could be completed by changing the die.

The shearing unit also adopt column frame that will provide more power for the knife, the upper and lower knife was installed vertical parallelly, the single shearing mode ensure the kerf smooth with no waste.

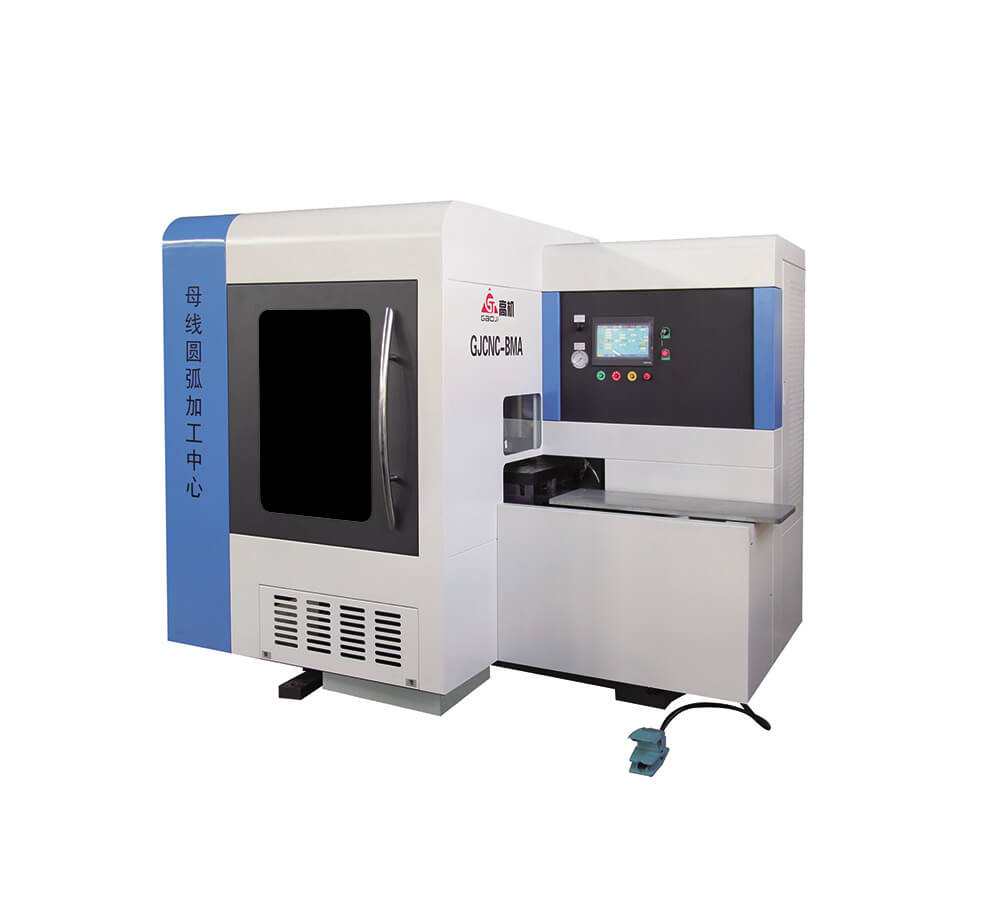

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

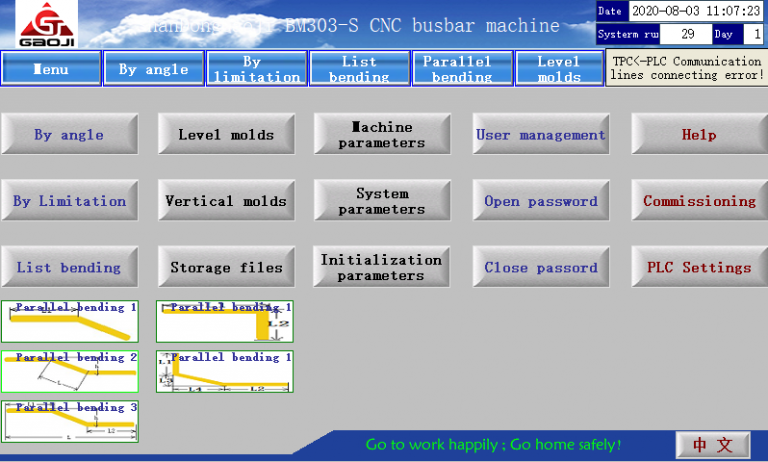

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for China Wholesale Hydraulic Busbar Bending Cutting Punching Machines Factories - Multifunction busbar 3 in 1 processing machine BM603-S-3 – Gaoji, The product will supply to all over the world, such as: Netherlands, belarus, Mexico, Our items are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!