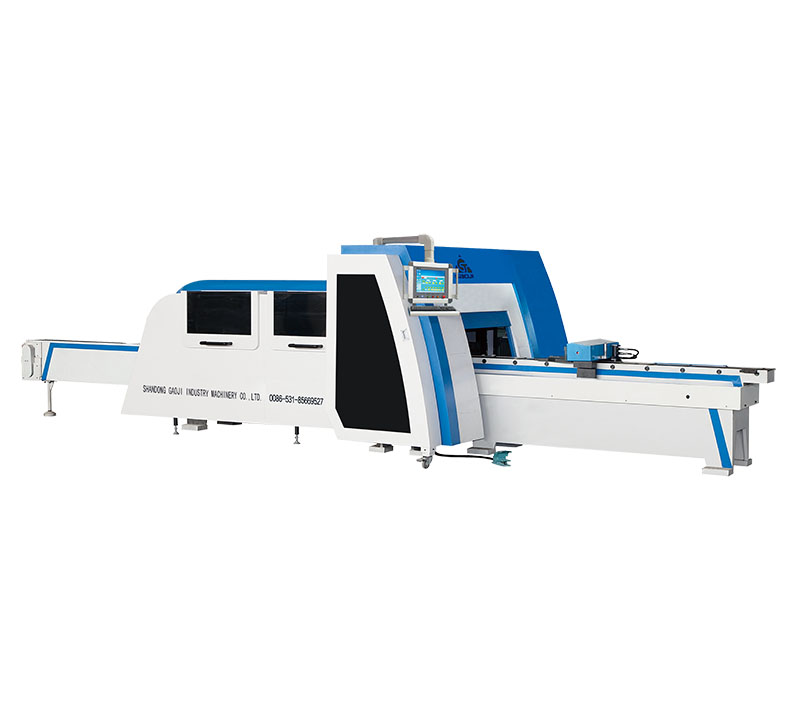

China Wholesale Offset Bend Copper Pipe Pricelist - CNC Busbar servo bending machine GJCNC-BB-S – Gaoji

China Wholesale Offset Bend Copper Pipe Pricelist - CNC Busbar servo bending machine GJCNC-BB-S – Gaoji Detail:

Product Details

GJCNC-BB Series are designed to bend busbar workpiece efficiently and accurately

CNC Busbar Bender is special busbar bending processing equipment controlled by computer, Through X-axis and Y-axis coordination, manual feeding, the machine can finish different types of bending actions like level bending, vertical bending through selection of different dies. The machine can match with GJ3D software, which can accurately calculate the bending extension length. The software can automatically find the bending sequence for the workpiece that requires several times bending and the programming automation is realized.

Main Character

Features of GJCNC-BB-30-2.0

This machine adopts unique closed type bending structure, it possesses the premium property of the closed type bending, and it also has the convenience of the open type bending.

The Bend Unit(Y-axis) has the function of angle error compensation, its bending accuracy can meet the high performance norm. ±01°.

When it is in vertical bending, the machine has the function of auto clamping and release, the processing efficiency is greatly improved compared with manual clamping and release.

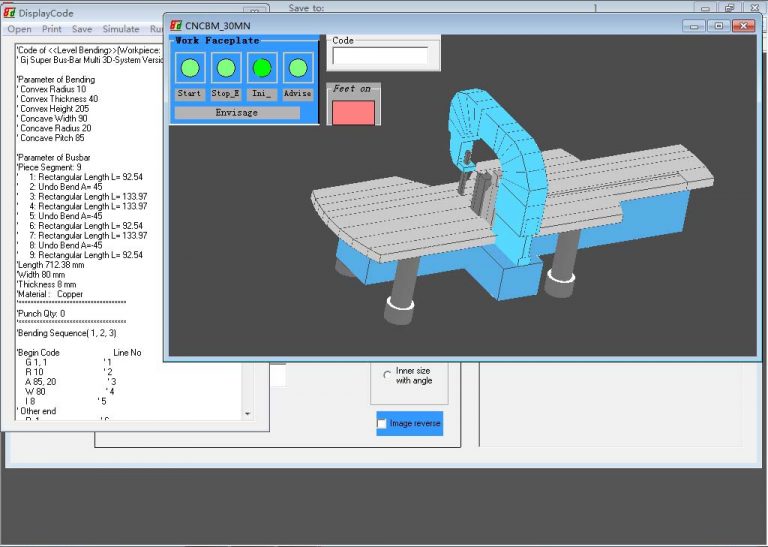

GJ3D Programming software

Inorder to realize auto coding, convenient and easy operate, we design and develop the special aided design software GJ3D. This software can automatically calculate every date within the whole busbar processing, so it’s able to avoid material waste cause by error of manual coding; and as the first company apply 3D technology to busbar processing industry, the software could demonstrate the whole process with 3D model which is more clear and helpful than ever.

If you need to modify the equipment’s setup information or basic die parameters. You can also input the date with this unit.

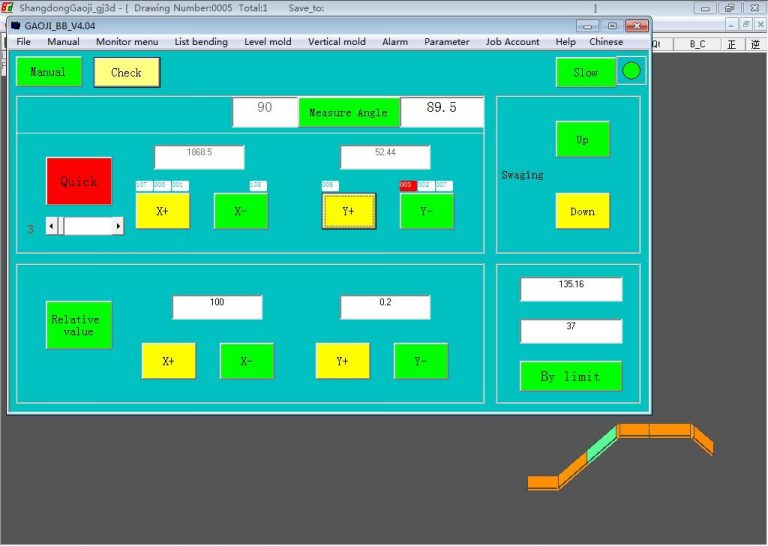

Touch Screen

Human-computer interface, the operation is simple and can demonstrate real-time the operation status of the program, the screen can show the alarm information of the machine; it can set the basic die parameters and control the machine operation.

High Speed Operation System

High accurate ball screw transmission, coordinated with high accurate straight guide, high precision, fast effective, long service time and no noise.

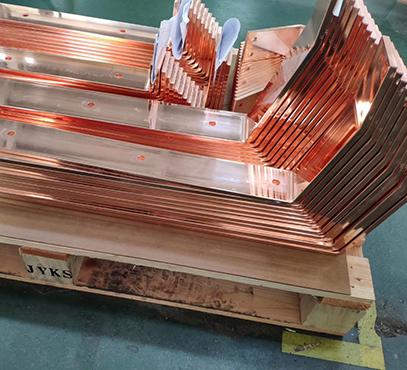

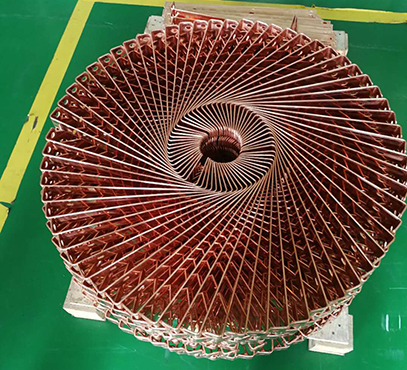

Workpiece

Product detail pictures:

Related Product Guide:

The corporate keeps towards the operation concept "scientific administration, superior quality and performance primacy, client supreme for China Wholesale Offset Bend Copper Pipe Pricelist - CNC Busbar servo bending machine GJCNC-BB-S – Gaoji, The product will supply to all over the world, such as: Juventus, Vietnam, Anguilla, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.