China Wholesale Busbar Punching And Shearing Machine Quotes - Hot New Products China CNC Automatic Busbar Arc Chamfering Machine – Gaoji

China Wholesale Busbar Punching And Shearing Machine Quotes - Hot New Products China CNC Automatic Busbar Arc Chamfering Machine – Gaoji Detail:

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Hot New Products China CNC Automatic Busbar Arc Chamfering Machine, We guaranteed good quality, if consumers were not satisfied with the products’ good quality, you can return inside of 7days with their original states.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for China Busbar Chamfering Machine, Copper Busbar Machine, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Product Details

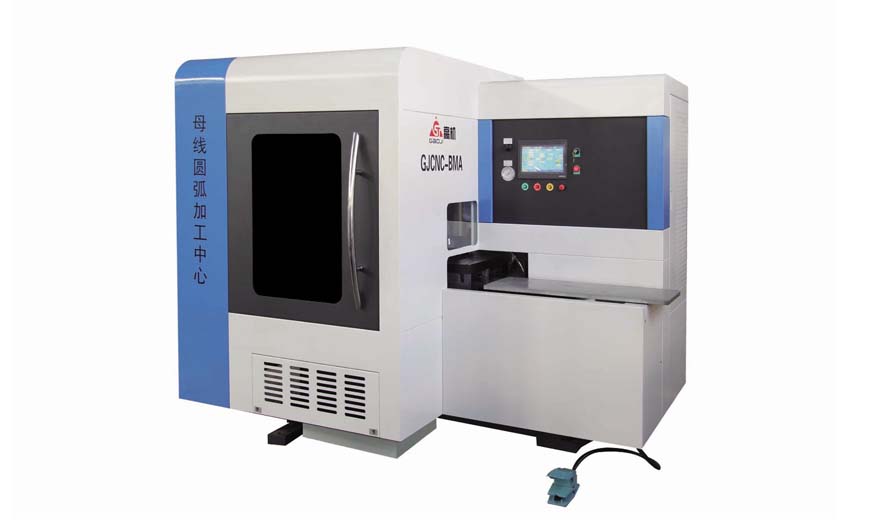

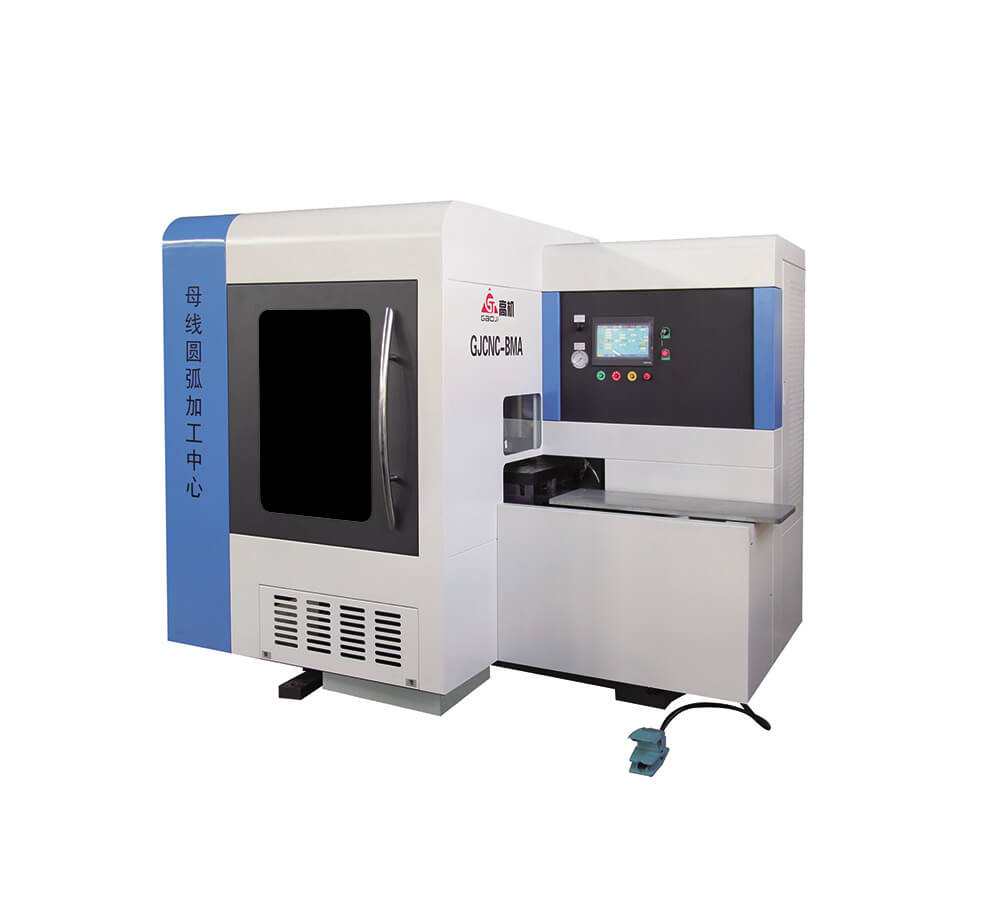

CNC busbar milling machine mainly functions in milling fillet and big fillet in the busbar. It automatically generates the program code and transmits the code to the equipment basing on the requirements on the busbar specification and the data input onto the display screen. It is easy to operate and can machine useful busbar arc with nice looking.

Advantage

This machine is used to carry out sectional arc machining for busbar heads with the H≤3-15mm, w≤140mm and L≥280mm.

The bar head will be machined to the shape with fixed structure.

The clamps adopt automatic centering technology to press the pressing head better onto the force bearing point.

A booster is used on the pressing head to secure the stability of workpiece, rendering a better machining surface effect.

World standard BT40 tool holder is used for easy blade replacement, fine rigidity and high accuracy.

This machine adopts high-precision ball screws and linear guides. Heavy-load large-size guide rails have been selected to offer better rigidity of the entire machine, lower the vibration and noise, improve the quality of workpiece and ensure high accuracy and efficiency.

Using components of domestic and world famous brands, this machine is of long service life and can guarantee high quality.

The program used in this machine is the embedded automatic graphics programming software developed by our company, realizing the automation in programming. The operator does not have to understand various codes, nor does he/she have to know how to operate the traditional machining center. The operator just has to enter several parameters by referring to the graphics, and the equipment will generate automatically the machine codes. It takes shorter time than manual programming and eliminates the potential of code error caused by manual programming.

Busbar machined in this machine is of fine look, without point discharge, narrowing the cabinet size to save space and remarkably reducing the consumption of copper.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Hot New Products China CNC Automatic Copper High Effiency Processing Bending Punching Cutting Machine Busbar Arc Chamfering Machine, We guaranteed good quality, if consumers were not satisfied with the products’ good quality, you can return inside of 7days with their original states.

Hot New Products China Busbar Chamfering Machine, Copper Busbar Machine, Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for China Wholesale Busbar Punching And Shearing Machine Quotes - Hot New Products China CNC Automatic Busbar Arc Chamfering Machine – Gaoji, The product will supply to all over the world, such as: Boston, Iraq, Kazakhstan, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers' benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.