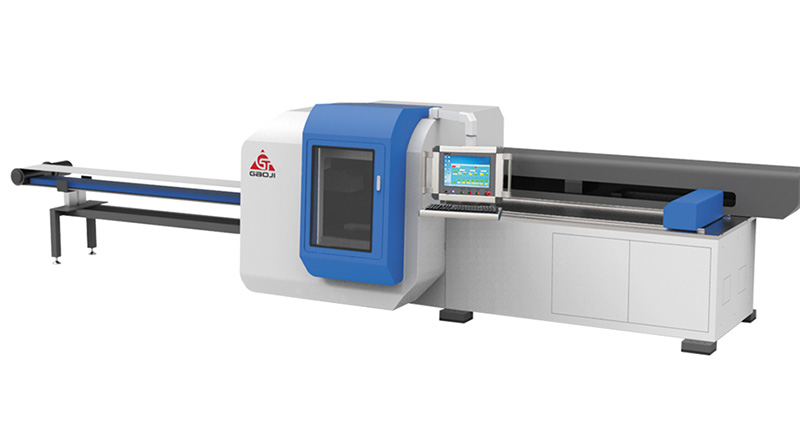

CNC Bus Duct Flaring Machine GJCNC-BD

Main functions and Features

GJCNC-BD series CNC Busduct Flaring Machine is the Hi-Tech production machinery developed by our company , With auto feeding ,sawing and flaring functions( Other functions of punching, notching and contact riveting etc are optional ) .System adopt individual control system ,auto busduct input as well real time monition for each process , assuring more safety, easy, flexible . Improve automatic grade and capacity of busduct .

Rogram Software GJBD: Before operation, input the data of busduct and saved, automatic generate PLC code and start process.

Automatic Process Flow: Load Bus bar Manually, Aided Clamp auto engage and feed, auto clamp,sawing and flaring etc (Optional function: punching, notching,contactor riveting : Contact Cabin feed contact automatically and realize automatic contact riveting.

Double Clamp: Main and Aided clamps. Max X stroke is 1500mm .Using Double Clamp with individual servo motor controlled , realize Auto clamp busbar , labor saving , high efficiency and Accuracy.

Quick Conveyor : Finished work piece discharged automatically by quick stainless conveyor , Efficiency and assure no scratch to work piec.

Touschreen HMI : Human-Machine Interface (HMI) ,easy operation, real time monitor process status, Alarm record and simple Mould Setup as well operation process.

High-Speed Transmission System: Machine transmitting parts use high quality,accurate and efficient ball screw and guide linear ,driven by Servo motor , assuring processing quality and accuracy.All components are international famous brand , good quality and endurable life.

Machine Structure: Machine body welded with high-temp tempering in time , simple structure but good rigidness.

Tool Kit Cabin(Optional): Stock all tools and change mould more simple,safe and convenient .

| Description | Unit | Parameter | |

| Force | Punching | kN | 300 |

| Notching | kN | 300 | |

| Riveting | kN | 300 | |

| Cutting | Circular Size | mm | 305 |

| Revolution | r/m | 2800 | |

| Motor Power | kw | 3 | |

| Max X1-Way Stroke | mm | 1500 | |

| Max X2-Way Stroke | mm | 5o0 | |

| Max Y1-Way Stroke | mm | 350 | |

| Max Y2-Way Stroke | mm | 250 | |

| Max Flaring Height | mm | 30 | |

| Station | Circular | Set | 1 |

| Flare | Set | 1 | |

| Punch | set | 1 (Option) | |

| Notch | Set | 1 (Option) | |

| Contact Rivet | Set | 1 (Option) | |

| Control | Axis | 4 | |

| Hole Pitch Accuracy | mm/m | ±0.20 | |

| Air Source | MPa | 0.6~0.8 | |

| Total Power | kW | 17 | |

| Max Busbar Size (LxWxT) | mm | 6000×200×6(Other Size Customeized) | |

| Min Busbar Size (LxW×T) | mm | 3000×30×3 (Other Size Cstomerized ) | |

| Machine Size: LxW | mm | 4000×2200 | |

| Machine Weight | kg | 5000 | |