100% Original China Multi-Staiton Bus Bars Punching Bending Shearing Machine

Usually customer-oriented, and it’s our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for 100% Original China Multi-Staiton Bus Bars Punching Bending Shearing Machine, Our enterprise warmly welcome close friends from everywhere in the environment to go to, examine and negotiate organization.

Usually customer-oriented, and it’s our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for 3 In 1 Busbar Machine, China Bus Bars Processing Machine, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Product Description

BM303-S-3 Series are multifunction busbar processing machines designed by our company (patent number: CN200620086068.7). This equipment could do punching, shearing and bending all at the same time.

Advantage

With appropriate dies, the punching unit could process round, oblong and square holes or emboss a 60*120mm area on busbar, and also could flattening or shearing copper stick.

This unit adopts round integral structure , the operator could replace the punching dies within 2 minutes.

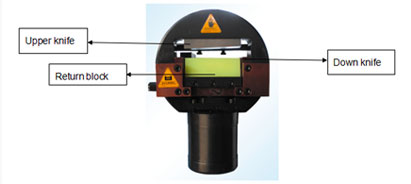

The shearing unit choose the single shear method, make no scrap while shearing the material.

And this unit adopts round integral structure which is effective and capable of long service life.

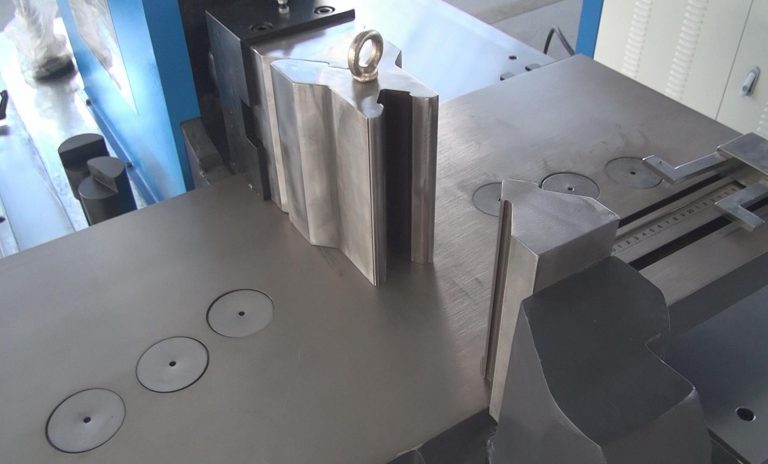

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

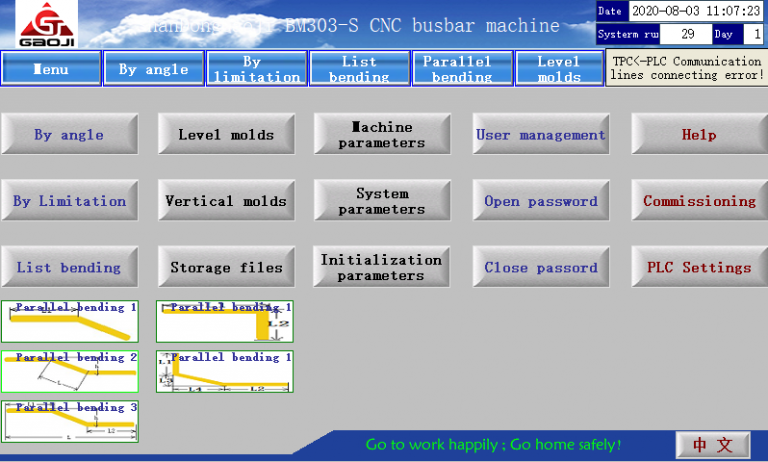

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

Usually customer-oriented, and it’s our ultimate focus on being not only one of the most responsible, trustable and honest provider, but also the partner for our clients for 100% Original China Multi-Staiton Bus Bars Punching Bending Shearing Machine, Our enterprise warmly welcome close friends from everywhere in the environment to go to, examine and negotiate organization.

100% Original China Bus Bars Processing Machine, 3 in 1 Busbar Machine, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Configuration

| Work Bench Dimension (mm) | Machine Weight (kg) | Total Power (kw) | Working Voltage (V) | Number of Hydraulic Unit (Pic*Mpa) | Control Model |

| Layer I: 1500*1200Layer II: 840*370 | 1280 | 11.37 | 380 | 3*31.5 | PLC+CNCangel bending |

Main Technical Parameters

| Material | Processing Limite (mm) | Max Output Force (kN) | ||

| Punching unit | Copper / Aluminum | ∅32 (thickness≤10) ∅25 (thickness≤15) | 350 | |

| Shearing unit | 15*160 (Single Shearing) 12*160 (Punching Shearing) | 350 | ||

| Bending unit | 15*160 (Vertical Bending) 12*120 (Horizontal Bending) | 350 | ||

| * All three units could be chosen or modify as customization. | ||||